- Best Practices

- Last Mile Delivery

10 Ways to Reduce Delivery Costs in 2024

by

Jennifer Collins

April 18, 2024

Keeping costs low is the key to survival in business, and this is particularly relevant when you are striving to stay competitive while still maintaining a high level of quality in goods and services.

When you analyze the costs involved in the sales order process, the most expensive part of the journey is delivery to the customer. Transportation is costly, and these costs are factored into the price of your product, ultimately affecting your competitiveness and profit margins.

Small businesses will boom in 2024 as e-commerce expands and social media and email marketing become the norm, empowering the growth of small and medium-sized operations that take advantage of these advertising strategies.

Cost considerations result in the need for tighter budget control

As the orders flow in, the logistics side of businesses becomes a hive of activity, and the costs mount up. It’s easy to lose track of just how much your logistical operation is costing. We’d like to share some of our expertise by providing you with ideas on how to reduce delivery-related expenses and optimize your delivery operations.

Rising costs of logistics and delivery services

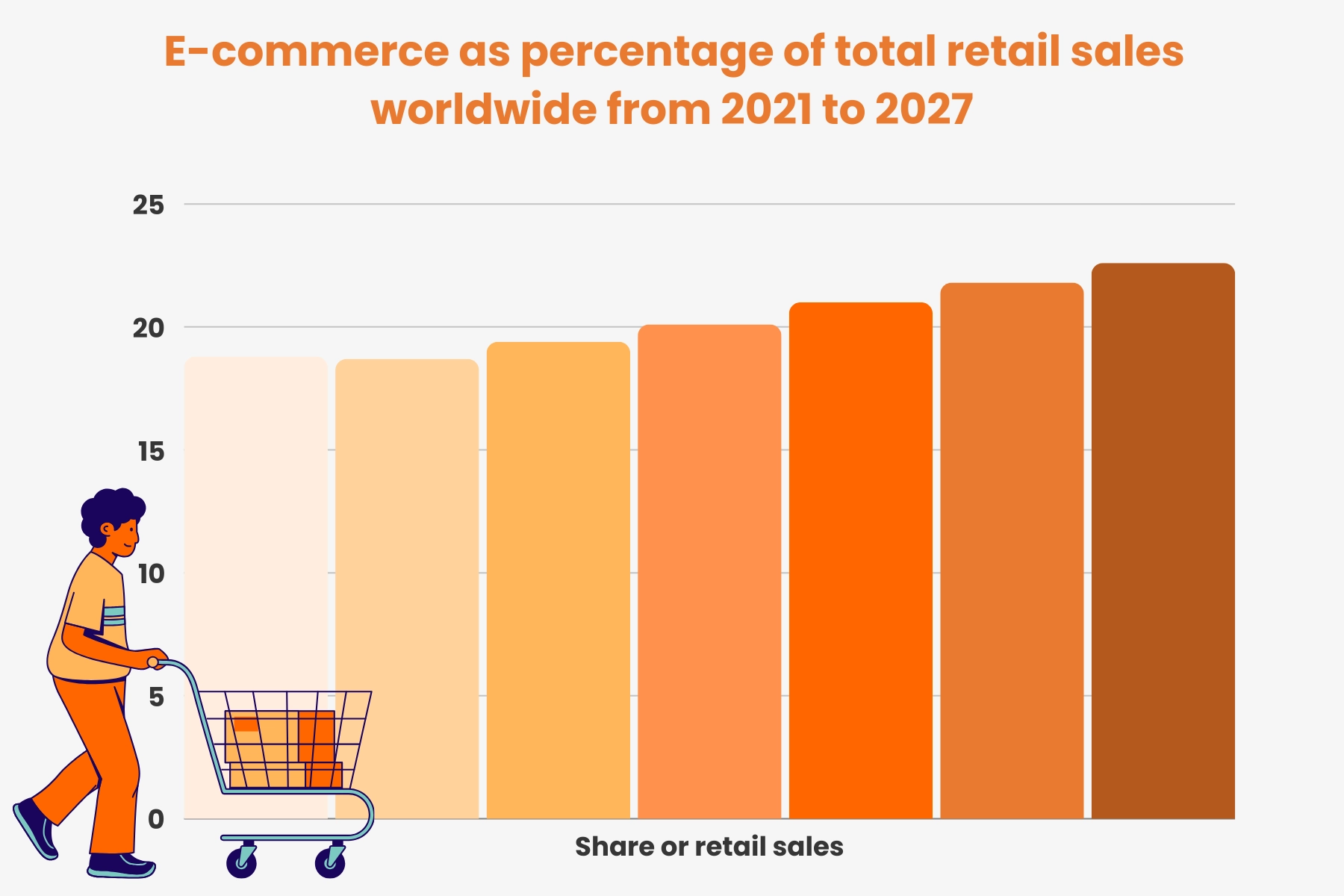

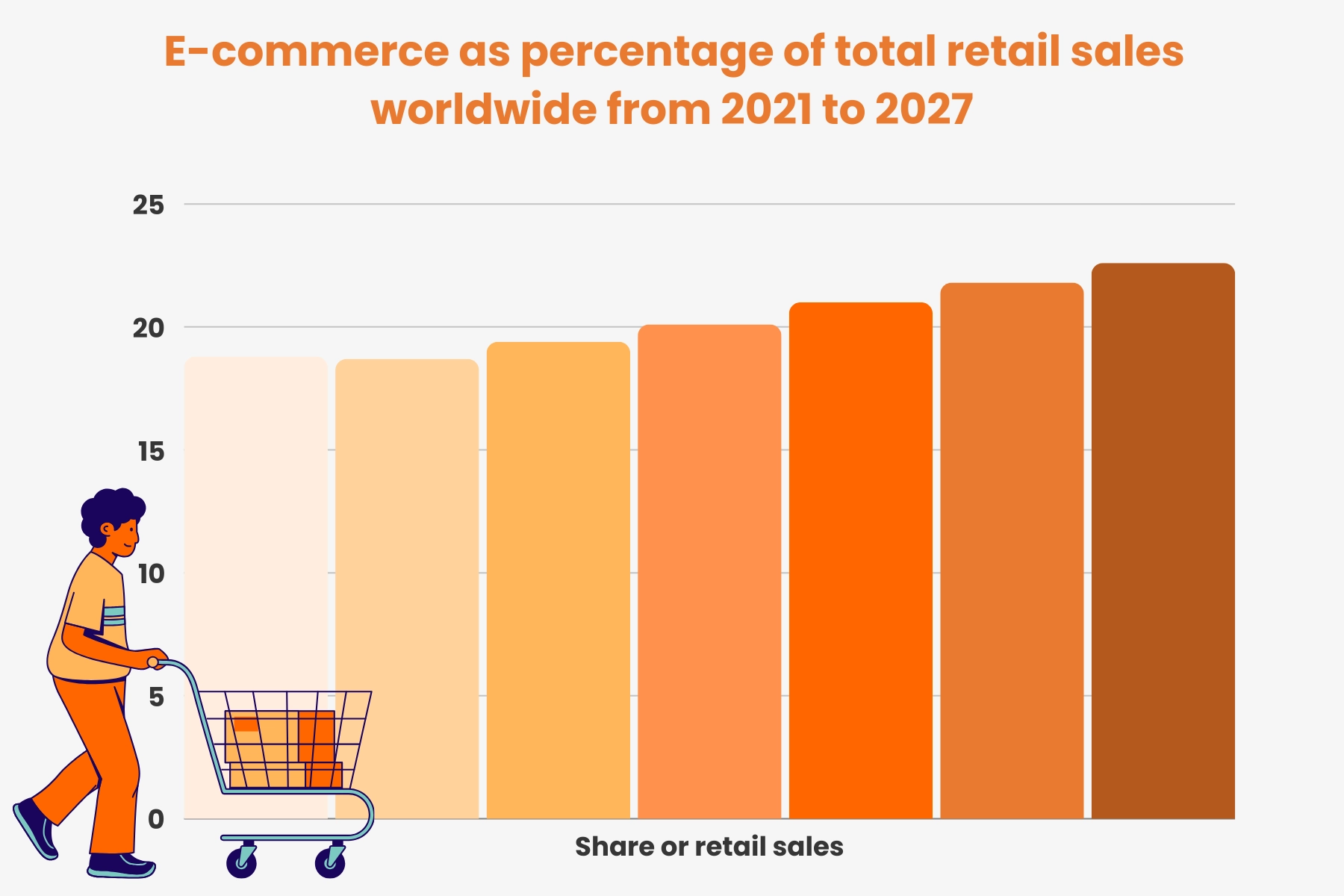

In today’s dynamic e-commerce environment, business is booming. In 2022, e-commerce accounted for 19 percent of retail sales worldwide, with forecasts for 2027 predicting a global retail sales figure of around 25 percent.

Source: Statista

As logistics and transportation companies strive to remain competitive, rising costs are playing havoc with their profit margins.

So, why is wholesale shipping so expensive? Global labor shortages in the trucking sector are a big culprit, as truck drivers are traditionally not well-paid, and their working conditions are far from ideal. The increase in logistics businesses has made it hard to find experienced personnel.

The first two quarters of 2024 see shipping trade disruptions

Freight costs in 2024 are currently more volatile than usual due to diversions in the Suez Canal caused by the Israeli-Hamas war-linked Red Sea crisis. Indiscriminate attacks on ships belonging to various nations are having a widespread effect on global trade as ships are re-routed around the southern tip of Africa, causing delays of 10 days on average.

At the same time, a severe Panama Canal drought has substantially slowed maritime operations in an area that usually accounts for five percent of global shipping trade.

Some freight companies are issuing the following advice:

- Compare a few quotes and modes (air freight) to ensure you get the best cost and service possible.

- Buffer your freight budget and time, and be prepared for unforeseen delays.

- Explore different warehousing options.

- Remember to factor in freight costs when assessing the profitability of your goods.

The impact of costs on profit margins

Transport costs can escalate quite substantially due to unforeseen occurrences, such as breakdowns in remote locations. This scenario could involve additional accommodation costs, overtime rates, and expensive repairs or towing fees. You may have budgeted for the maintenance of your vehicles, but these unforeseen costs make huge dents in your cash flow and affect your profitability.

On a smaller scale, daily costs that are almost undetectable will slowly eat away at your profits if unchecked, and the net result over time can be pretty devastating. It’s vitally important that you monitor these costs constantly to remain profitable.

Cost breakdown of delivery operations

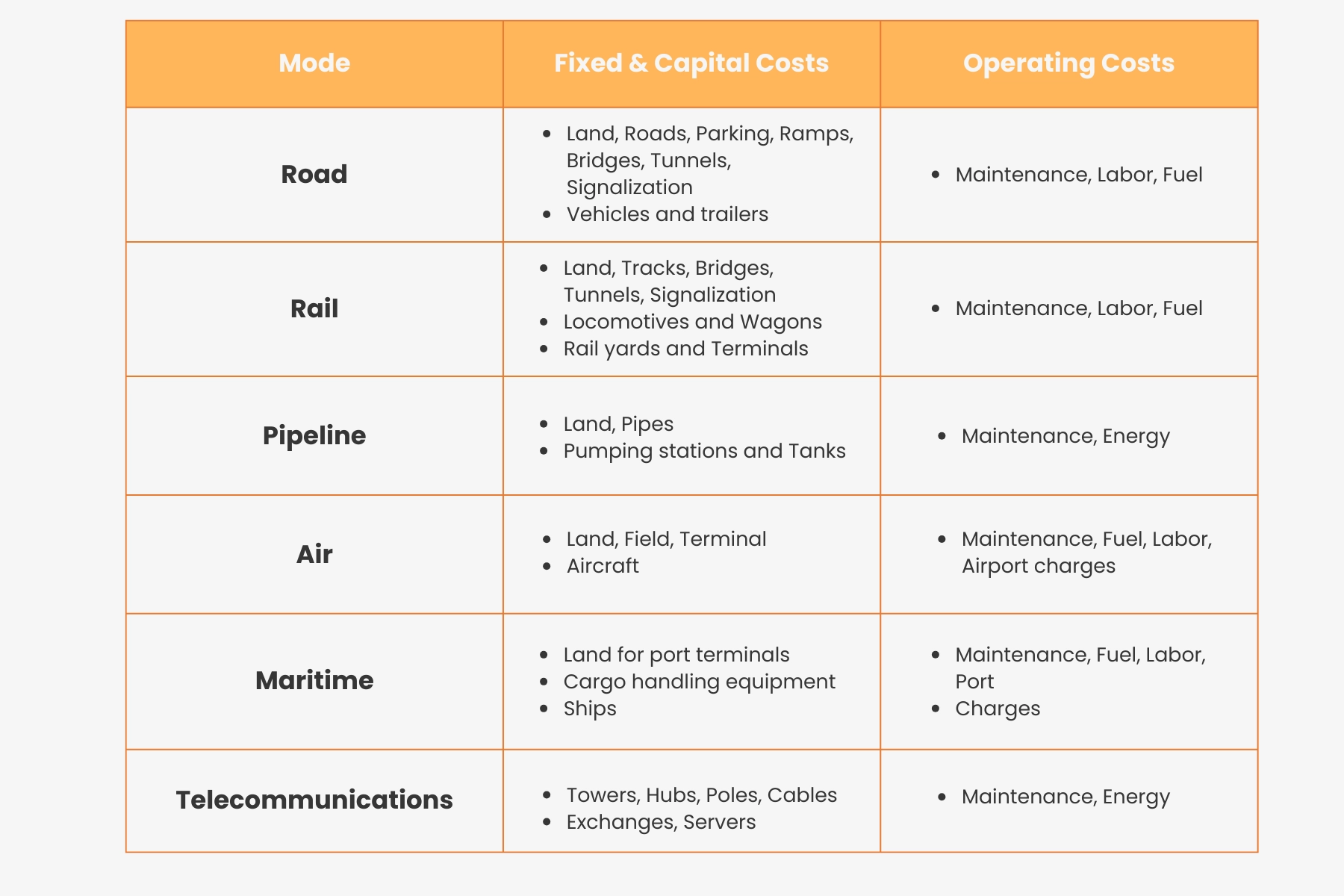

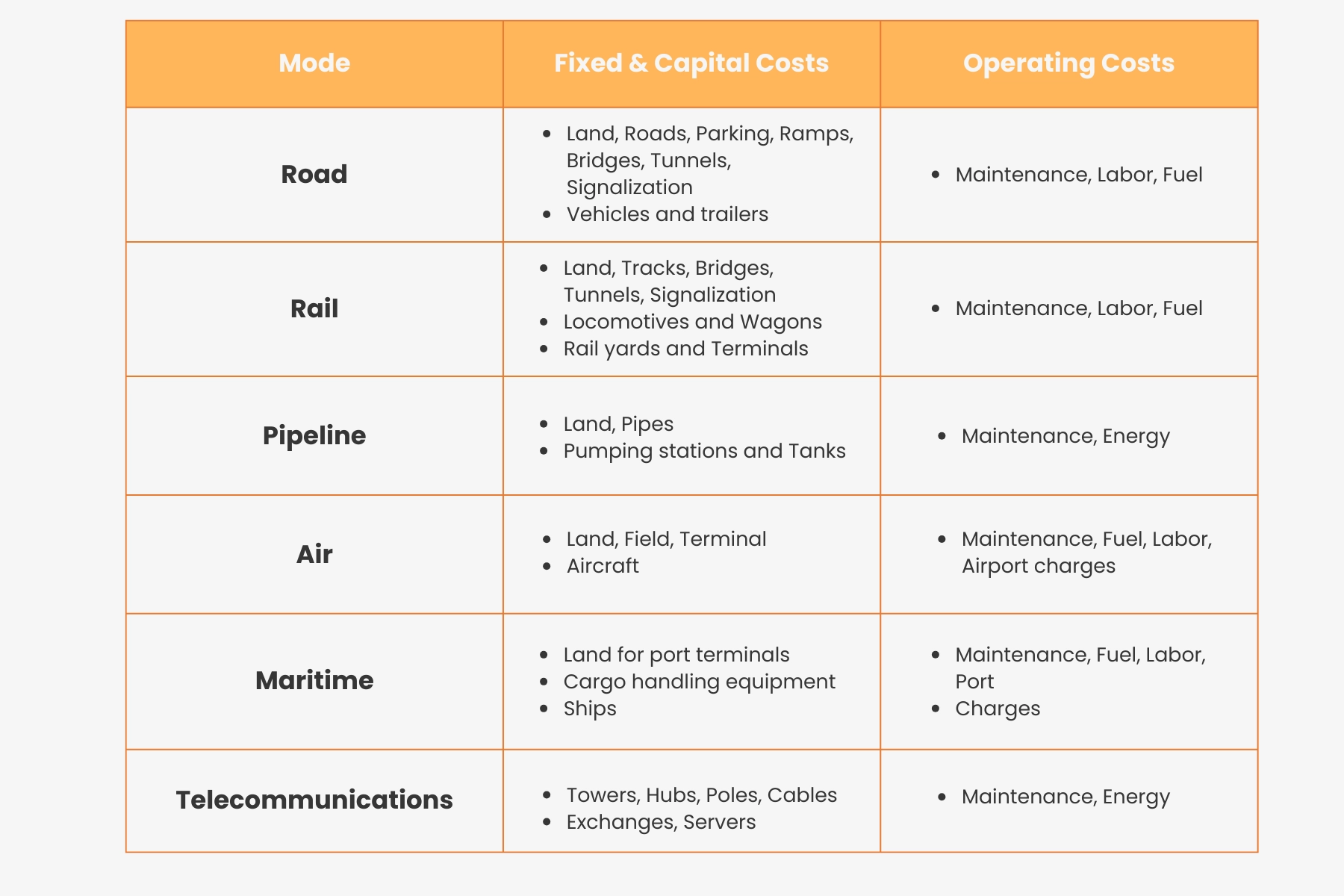

Transport costs can be divided into fixed and variable costs, with fixed costs being vehicles and trailers and infrastructure such as roads and parking. Variable costs are operating costs, such as fuel, maintenance, and labor. When traveling further afield, cargo attracts additional customs, port charges, or airport fees.

Source: TransportGeography

The type of freight may also impact costs; for example, hazardous or fragile materials need additional packaging, security, and insurance.

Variable costs also escalate depending on the distances traveled, where you must pay drivers overtime wages due to long-distance travel and other incidental expenses such as meals and toll fees.

Manual systems that involve time spent on tedious documentation also take their toll on the company’s resources.

Refrigeration may be another substantial cost for transporting perishable goods, and the urgency of getting the goods delivered can put additional pressure on your costing structures. Efficient routing software for these specialized trucks would mean substantial savings in fuel and refrigeration costs.

Efficiency gains through optimization

A typical knee-jerk reaction to rising shipping costs is for managers to increase the prices of their products. However, this just pushes inflation even further and is not a long-term solution.

Operations optimization will reduce costs and empower management to maintain their cost structures and remain competitive. They are also likely to improve sales, not only as a result of competitive pricing, but efficient communications and delivery times will undeniably impress their customers as well.

Optimization of your logistics operation means automating as many processes as possible so that you save time and free up valuable resources.

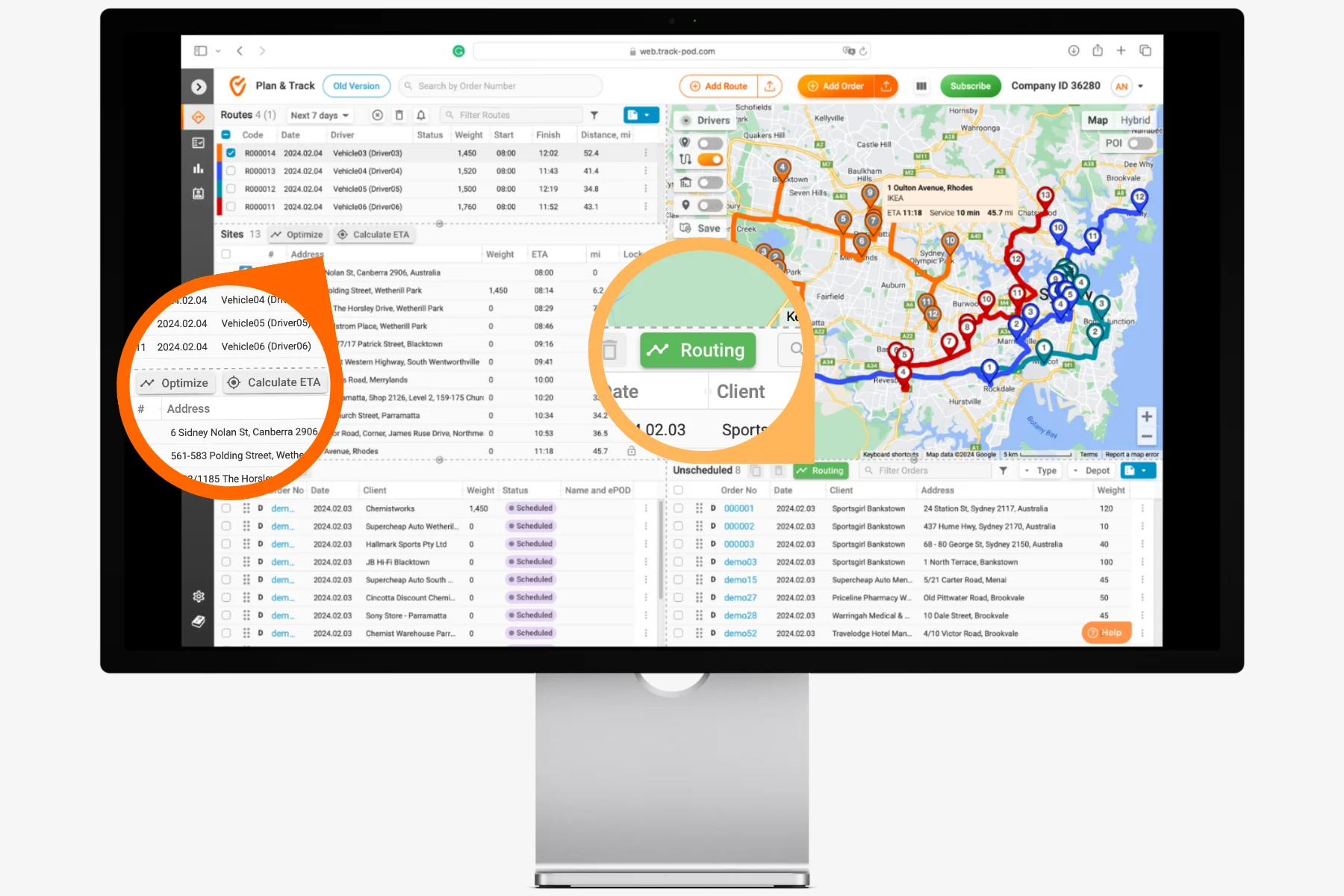

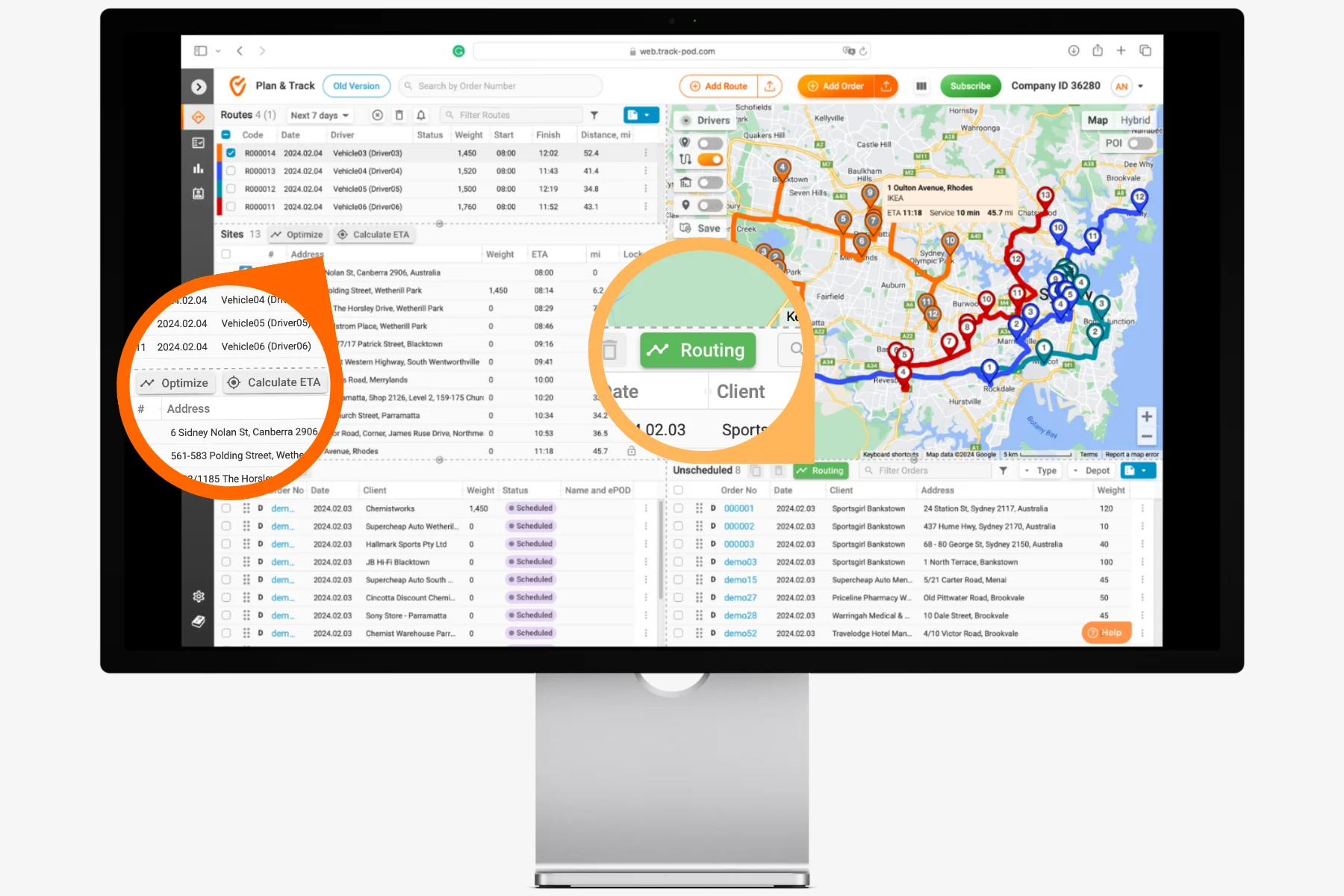

Route optimization will cut down on vehicle usage and driver time, and it will save fuel and long-term maintenance costs. Automating delivery route planning will plot the best routes with the fastest delivery times and fuel savings possible.

Most systems also consider multiple vehicles when planning routes and determine which vehicles can take additional weight or specialized cargo, such as perishables, so that you can optimize the deliveries per vehicle and area. Some automatic routing software includes functionality for returns and collections, as well as providing documentation to record customer receipts.

Keep your finger on the pulse with digital tracking devices in your vehicles, enabling you to track delivery times, idle times, and vehicle performance. Driver fatigue is a massive problem in the transport industry, and access to monitoring data helps enforce rest stops, which minimizes the risk of accidents. Knowledge of vehicle and driver performance enables you to improve your operations in terms of additional driver training and vehicle tuning.

Improved communications and reporting empower customers to track their deliveries and dispatch managers to make decisions regarding traffic snarl-ups, late deliveries, and the re-routing of vehicles. Improved visibility and communication will also likely speed up deliveries and impress your customers.

Automating delivery functions such as paperless documentation and route planning saves employees time. Giving customers access to track their deliveries means fewer inbound phone calls and fewer inquiries.

The last mile of the delivery process is often the most problematic, as unexpected delays waste time and cause costs to escalate considerably. Simplify as much of the last-mile process as possible by providing your drivers with the means to communicate with customers along the route and automate documentation such as electronic proof of delivery (ePOD) notifications to effect faster drop-off times.

Some real-world examples

Companies embracing technology to scale their operations and streamline delivery processes are thriving and expanding.

SIUNTŲ PILOTAI, aka Eagleship MB, a courier company that needed to expand its business, realized that its system of emails and Excel spreadsheets for customer orders was no longer sustainable. Since using the Track-POD customer portal, they have managed to secure their biggest customer and are still expanding, aided by the complete Track-POD suite of delivery solutions.

Additional features such as bar code scanning and customized shipment labels have made that extra difference, helping them save time and cut costs.

On a larger scale, Skuba, a truck and trailer expert with 180 branches and over 100 drivers, found that planning efficient routes between their branches and drivers presented many challenges and affected their efficiency. Since automating their route planning and tracking facilities, they have doubled their efficiency and delivered the customers’ products within two hours of an order being placed.

Environmental impact

We’re all aware of the pressure being placed on the environment by carbon emissions emitted from the various modes of transport. Still, transportation also leads to noise and water pollution. It has an indirect impact on human and animal lung and cardiovascular systems and the millions of eco systems worldwide.

That said, climate change may also adversely affect the transportation industry. Increased turbulence and heat-induced degradation affect aircraft, shipping lanes change due to ice caps melting, roads are affected by more freeze-thaw cycles, and intense heat in some areas can damage vehicles and trains.

With the rise in greenhouse gas emissions, pressure is being placed on transportation sectors in most countries, with policies being implemented for companies to become more sustainable and reduce their carbon footprint.

The use of drones may seem like an obvious solution to many; however, this method may have challenges in built-up areas. Drones are being used to deliver goods in remote areas, mainly when vehicles' drop-off points are inaccessible.

Electric vehicles and autonomous vehicles are alternate options; however, the technology is still new, and research is ongoing. They are likely to be expensive options for now, but it’s worth keeping an eye on developments.

However, the jury is still out on electric vehicles. They require twice as much energy to produce than fuel-driven vehicles and use large amounts of lithium, aluminum, copper, and cobalt. To make them a sustainable resource, the batteries need to be used for as long as possible and recycled once they reach their end-of-life. When electric vehicles are used in countries with clean energy sources, they are sustainable; however, their usage remains questionable in countries where electricity production is still carbon-intensive.

Regarding climate change and your transport operations, the least you can do to minimize your carbon footprint is to streamline your processes. Efficient route planning cuts down on unnecessary carbon emissions and fuel usage.

You can also look at eco-friendly packaging and go for a product with bio-degradable packaging manufactured according to sustainable standards.

Organize the packing space in your warehouse to reduce forklift movement, saving time and fuel.

10 ways to reduce your delivery costs

1. Optimize your routing

Vehicle routing software plots the quickest, most fuel-efficient route for your cargo, avoiding unnecessary drops and cutting fuel expenses. It saves time and resources, freeing up planning and driving personnel and vehicles.

2. Consider hybrid delivery models

You may be experiencing an upsurge in sales. You can’t deliver all of the products sold, or you may be experiencing problems with one or two of your vehicles that have compromised your capacity to deliver on time. You don’t want to lag, as this creates a bad impression, and those sales may dwindle again.

What is the cheapest shipping method for small businesses if you have a backlog of deliveries to deal with?

Outsourcing your deliveries to a third-party logistics company or to courier services is the next best thing to managing your deliveries. You can rest assured that these companies provide good service and can offer competitive rates, mainly if there is a promise of more business to come.

You can even outsource your entire delivery operation to a company of logistics specialists, allowing them to take care of the deliveries. At the same time, you focus on selling your products.

3. Bulk shipments

Whether on a small or large scale, bulk shipping can save you money. When you are shipping large quantities of goods, it makes sense to combine everything into one crate, box, or container, depending on the weight and size of the cargo, the mode of transport, and the distance to be traveled. You are more likely to obtain discounts on your transportation if you package your goods to make handling them easier and quicker for the transport company.

4. Negotiations with carriers

When outsourcing your deliveries, forming positive relationships with the transport company you entrust your cargo to is always beneficial.

Be prepared. Before negotiating, know the prices and currency rates and how they relate to your needs. Be aware of any political influences and market trends that may affect you.

Here’s what you need to discuss with prospective transportation agents:

- Tracking your cargo

- Quality assurance.

- Insurance

- A customer return process

- Cost reductions depending on increased volumes to be shipped

Read the fine print carefully and be careful of clauses such as limits on the time allowed for delivery and collection, additional charges for weekends and holidays, demurrage charges, and packing and unpacking fees. Use these points in your negotiations.

You can join up with other users and negotiate group rates. It’s easier to lock into fixed prices for six months when you have the buying power to do so.

Enquire about master carrier agreements, where you enter into a private agreement with the shipping company that gives you special rates. You then have a say in tariff changes and other costs.

5. Choose your packaging wisely

As per our discussion on sustainable packaging above, select light packaging to reduce the weight of your parcels.

- Aerothene, or bubble wrap, protects fragile goods but is made of plastic, making it unsustainable.

- Honeycomb cardboard options are less compact than normal cardboard and offer extra protection.

- Compostable resin made from wood or agricultural waste can be molded into shapes ideal for packaging, mainly foodstuffs.

- Composite packaging that is typically manufactured from cardboard, timber, and various low-density foams protects heavy and bulky items.

6. Implement local delivery

Companies that deliver goods locally often don’t pay attention to the weight and size of their packages. Slight reductions in the weight of many packages add up to substantial fuel savings on a daily delivery schedule. Tips on weight reduction include:

- Select the right-sized box for the item.

- Use lightweight packaging, such as corrugated cardboard.

- Lightweight straw-based packaging is suitable for protecting fragile items. Fiber ‘straws’ made from agricultural waste are biodegradable and inexpensive.

- Use ground delivery instead of air delivery if it makes sense.

- Consider teaming up with a 3PL company with a contract with a larger carrier company and getting discounted prices based on volume.

- Pay attention to delivery addresses. Returns because of incorrect address instructions cost money.

- Be wary of bundling options, as they may need to be more cost-effective in the long run.

- Audit your accessorial fees and delivery area surcharges if they are being charged, and develop alternative carriers if necessary.

- Some companies offer free packaging, so it may be worth investigating.

7. Go green with eco-friendly vehicles

Suppose you can justify the savings in running costs compared to the battery manufacturing and disposal costs, both economically and environmentally. In that case, electric vehicles will undoubtedly save substantial amounts of fuel. Providing sufficient charging stations en route offers a more cost-effective way of refueling.

8. Analyse and adjust shipping policies

A shipping policy is a statement to your customers regarding how you ship goods. It should be linked to your checkout facility on your e-commerce website for potential buyers to read.

It should be written without complicated legal jargon and include rates, timelines, local and international options, restrictions and exclusions, refund policies, money-back guarantees, your exchange policy, and how you handle shipping delays and missing or damaged packages.

Research done by the Baymard Institute indicates that 69 percent of shoppers abandon their purchases once they get to the cart, partially due to a poorly designed checkout design. 65 percent of websites don’t display their guest checkout options, scaring people away when they are required to transact with a company without transparency.

Because of the fast-paced nature of e-commerce and the transport industry, it is advisable to review your shipping policies frequently to ensure they are still compliant and up-to-date, mainly if you have included rates and timelines.

9. Reduce errors with the suitable systems in place

Errors in the initial capture of sales order information can be expensive. Incorrect delivery addresses are more common than we think, and inaccurate product descriptions or quantities often mean return trips and refunds. Educate your customers, and tweak your order entry system as far as possible to check for errors. AI should be able to identify nonsense when it appears in your system, so put it to good use.

10. Educate your customers on shipping costs

Regarding delivery costs, fixed and variable costs can make a difference to your pricing.

In the case of local deliveries, it usually comes down to faster delivery at a higher price or slower, cheaper methods.

It’s good practice to communicate these costs to your customers so that they understand what’s involved. Give them a list or table of prices and let them choose their preferred shipping method, knowing that their choice has cost implications.

You can also give them packaging options; however, do not compromise on the quality of your packaging, as you don’t want to be responsible for damages.

Offer free shipping if they purchase a minimum quantity or value, provided you can afford it. Bear in mind that you will inevitably gain extra sales with this strategy.

Check your competitors’ pricing to see whether you are still competitive or need adjustments.

Overseas shipping is more complex, with fluctuating costs. You can offer fixed or dynamic rates, and if you are offering sales on an e-commerce platform, you may have to link your website to a shipping carrier that can display the costs and calculate the rates for your customers.

Above all, be proactive

In the dynamic world of transportation, costs change daily, and the slightest change in weather or political situations can drastically affect exchange rates and delivery costs. These scenarios involve not just sales but your whole business operation, and it would be wise to have a dedicated person responsible for checking daily currency fluctuations and making adjustments in your business systems to accommodate these fluctuations and your costing variables when required.

This implies that you have a robust system to accommodate this type of costing without requiring too much manual intervention, as mistakes will inevitably result in lost revenue or, if your pricing is too high, lost sales.

Whether you use a spreadsheet with automated calculations or a competent ERP or delivery software solution, check your calculations and ensure your delivery costs are maintained regularly.

We hope we’ve been successful in giving you ideas on reducing shipping costs for small business operations and wholesalers.

About The Author

Jennifer Collins

A seasoned content writer with a passion for unraveling the intricate world of logistics through words.