8 Warehouse Innovations to Position Your Business for Growth

by

Alina Kostukova

June 19, 2023

Due to the rise of eCommerce, global supply chains, and increasing demand for next-day shipping, warehouses have to be more efficient than ever. Investing in innovation is essential—especially if you’re expecting your business to grow.

Without smart warehouse management and innovative technologies to help you, it’s easy to get overwhelmed or left behind by your competitors. A modern warehouse can easily handle order spikes, make operations more cost-effective, and build in flexibility for future evolution.

In this post, we’ll introduce you to eight warehouse innovations that will position your business for growth.

8 Warehouse innovations to position your business for growth

Now let’s take a look at some of the innovations that can help you overcome the challenges in warehousing and get ready to grow your business.

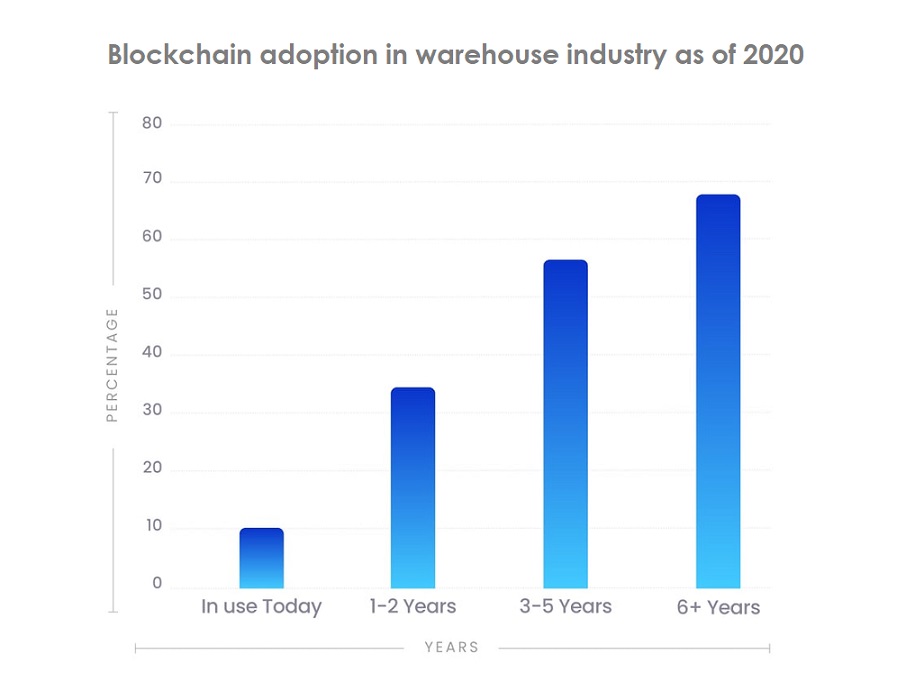

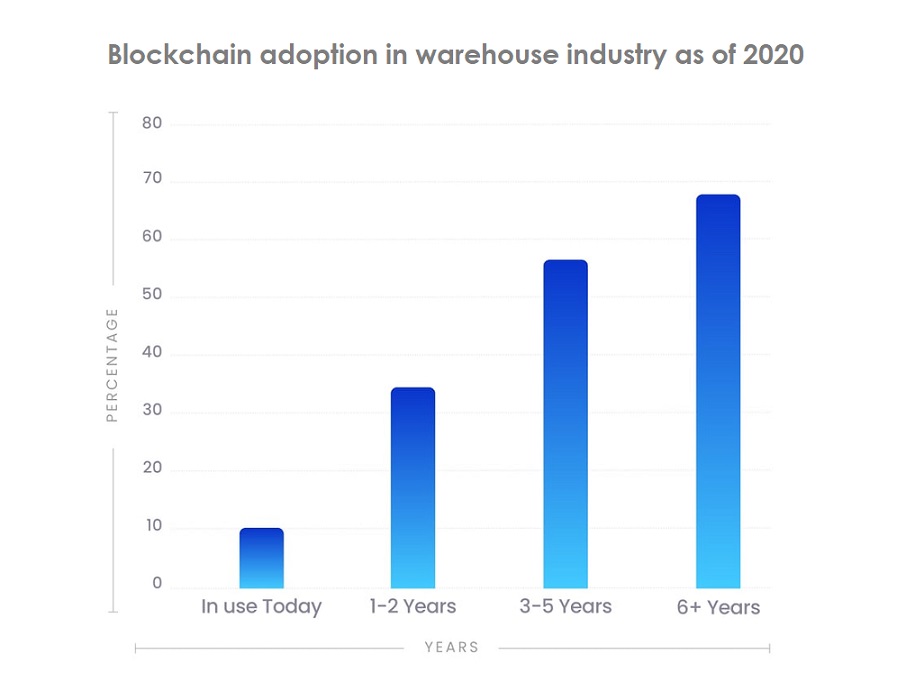

1. Blockchain applications

You might have heard of blockchain in relation to cryptocurrency, but it’s also becoming popular in warehousing. It’s a database that creates a chain made up of blocks of stored data. These blocks are secured and bound to each other using cryptographic principles, and the chain is permanent and incorruptible.

This makes blockchain a safe way to transfer information, as it’s resistant to cyberattacks and impossible to falsify transactions.

The method is also completely transparent, as information in a blockchain network can be viewed by anyone. This enhances data authentication and encourages collaboration.

With that in mind, blockchain can be used for warehouse activities because it enables you to track goods in real-time. It gives you a permanent record of every transaction that takes place and an audit trail that records the receipt of goods and automates supplier payments.

You can use the data to forecast future demand as you scale.

2. Warehouse management systems

Warehouse management systems (WMS) are comprehensive software solutions that act as a control center for managing your warehouse operations. They enable you to oversee all the processes involved in moving goods through the warehouse, as well as inventory control and labor management.

The ability to monitor everything and everyone at all times is invaluable as you expand to more warehouse locations.

By tracking performance, you can reveal opportunities for improvement, use automation to optimize manual processes and reduce operating costs—and make smarter business decisions.

It can also be integrated with your cloud ERP solution so you can harness real-time data and collaborate with teams in multiple locations. No hardware is required (so it’s low maintenance and energy-friendly), and you can easily add new users as you grow.

3. Warehouse drones and collaborative bots

The machines haven’t taken over just yet. For now, businesses are using robots to enhance rather than replace human labor.

Collaborative robots, or “cobots”, are designed to work together with humans.

The idea is to let the bots handle repetitive and labor-intensive tasks, boosting productivity—which means you’ll be able to expand your operations without taking on extra staff.

For example, cobots help with tasks such as loading and unloading of pallets and transporting goods to picking and packing stations to reduce walking time.

You can also optimize your warehouse by storing products in confined spaces or on high shelves since the cobots can retrieve them when a human can’t. They can also lift heavy items or hazardous materials.

Autonomous drones are another example of robots existing alongside humans. Smart drones use indoor geolocation technology to avoid obstacles. They can help to manage inventory by locating items through barcodes and taking photos or videos of products on shelves.

They’ll speed up cycle counting and look out for damaged or missing stock, as well as monitor safety conditions such as trip or spill hazards and equipment malfunctions. They can act as security guards around the clock, both inside and outside the warehouse.

Both drones and cobots are easy to implement and integrate, with minimal changes to existing warehouse layouts.

As well as saving money through efficiency, they give you added flexibility as you can rent additional machines during periods of high demand. You can monitor how well they work and decide whether to add further automation in the future.

4. Real-time tracking and monitoring

The ability to track processes, goods, and staff in real-time is a warehouse innovation you can’t live without. For example, smart software powered by advanced web development tools helps you check the availability, location, and condition of your inventory.

Smart shelves can tell you when an item is running low, while sensors monitor the temperature of perishable products.

Human operatives can easily locate goods through RFID (radio frequency identification) tagging or barcoding and scan packages before delivery to check whether the right cargo is headed in the right direction.

Using IoT sensors, you can track and synchronize all devices connected to your WMS, including autonomous vehicles, drones, and smart pallets.

Tracking helps you evaluate how long your basic processes take, such as the time taken to get orders from shelf to delivery pickup station. By leveraging powerful time recording software, you can also track staff attendance, monitor performance, and streamline labor scheduling.

Adding this kind of HR technology minimizes overworking, enables you to set realistic goals and deadlines, and empowers you to effectively manage your human resources.

5. Wearables and hands-free devices

Wearable technology has several benefits for the warehouse. For example, smart glasses and intelligent gloves have built-in scanners for product information, helping workers to locate items and send information back to the WMS.

Location-tracking wristbands monitor productivity and allow warehouse managers to assign tasks to the nearest operative.

Wearable devices are also used as a health and safety measure. They can check a worker’s posture and collect biometric data such as heart rate and temperature. It’s even possible to use a wearable robotic exoskeleton, which makes it easier to lift heavy objects by reducing strain on the back, knees, and wrists.

The other advantage of wearables is that they’re largely hands-free. The wearer can move around freely and use both hands to retrieve an item or pack a box without having to juggle any hand-held devices.

A pick-to-voice system is hands-free, eyes-free, and paper-free, only requiring a headset.

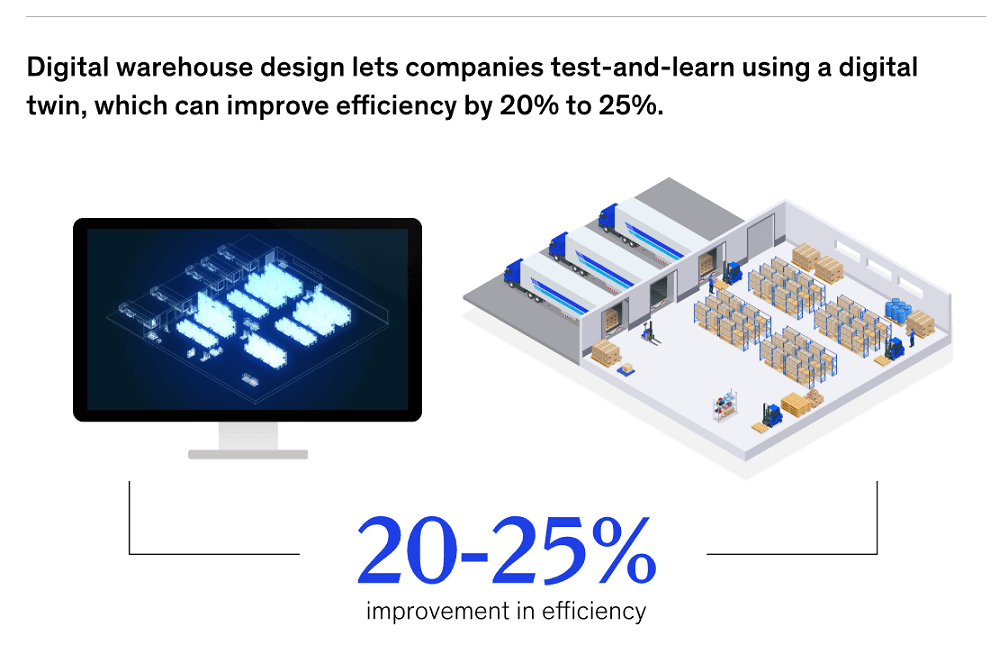

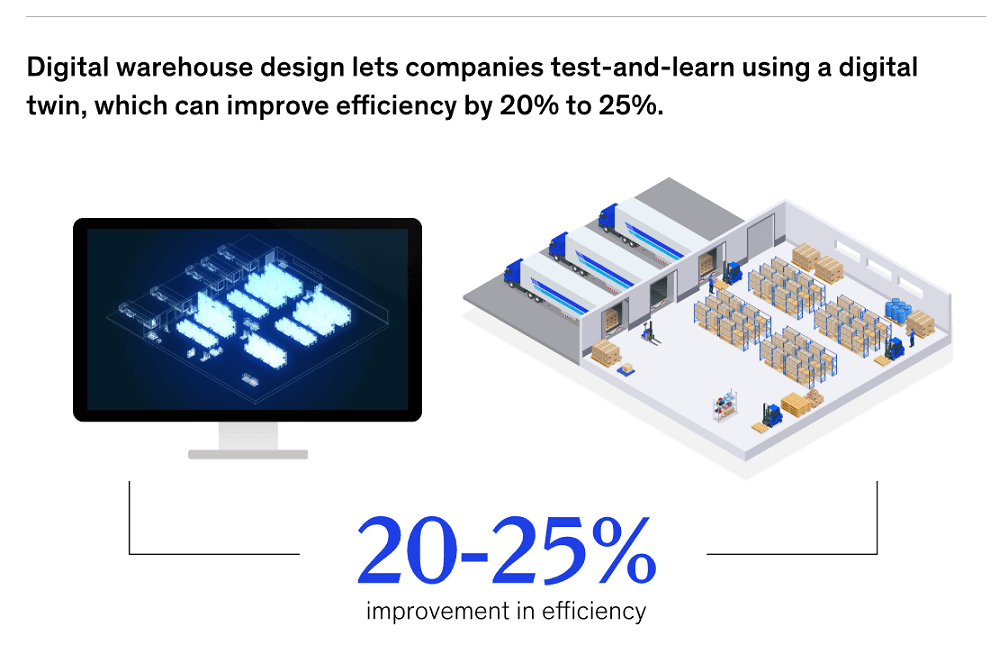

6. Digital twin technology

When you’re preparing for business growth, it can be hard to predict the warehouse size or layout you’re going to need. And you can’t shut down your operations while you test out new workflows or automated solutions. That’s where digital twin technology comes in.

A digital twin is a virtual, real-time representation or model of your existing warehouse in which you can simulate various scenarios such as alternate layouts, higher order volumes, or the presence of cobots.

The model is based on data extracted from your WMS, plus images taken by drones with 2D scanners.

Digital modeling helps you visualize your operations and see what is possible in the ideal warehouse, as well as the potential improvements from any proposed change. That way, you can be confident it’s going to work before you make any investment decisions or open a new warehouse site.

7. VR/AR immersive training

Virtual reality and augmented reality are ideal tools for warehouse training, whether it’s about learning new skills or understanding workplace safety protocols.

Warehouse employees can be trained for real scenarios without any risk of physical danger, damage to goods, or delays to operations.

This technology is useful for onboarding new hires and improving decision-making through visualization. You could add elements of gamification to boost engagement. For things like forklift training, you don’t need to wait for an actual vehicle to become available because the person can practice virtually.

You can create personalized training packages and monitor the progress of trainees. Another application is remote warehouse tours, in which employees and stakeholders can “visit” and interact with warehouses anywhere in the world.

8. Sustainable warehousing

As businesses and customers become more eco-aware, green logistics has become big news. This includes sustainable warehouses, which can save you money as well as saving the planet.

For example, you can use technology to design optimized layouts that take up less space, and replace bulky conveyors with mobile robots.

Efficient storage and inventory control also means you can use smaller premises, but even in larger warehouses, it’s getting easier to reduce energy consumption. You can use electrical power instead of fuel-powered machinery or install solar panels. At times when human staff are not present, robots and drones can operate without light or heat.

By closely monitoring your goods, you can make sure they’re stored in optimum conditions and reduce waste through spoilage or careless handling.

Accurate demand forecasting helps you to avoid being left with excess stock. You could reuse or recycle warehouse equipment and use sustainable packaging materials.

Finally, you could consider on-demand warehousing, where companies with vacant warehouse space rent out the space to those who need it. This helps to guarantee that available space is maximized so existing warehouses don’t stand half-empty while new ones are built.

Beyond specific warehouse solutions, Dynamic Business Technologies — such as real-time analytics and automated decision systems — are transforming how logistics and warehousing scale with demand.

Key takeaways

Implementing innovation in the warehouse is the ideal way to position your business for growth and make sure you’re ready for the future. Warehouse automation and collaborative robots will increase productivity, accuracy, and efficiency—so you can process orders faster to meet customer expectations.

You’ll also be able to maximize resource usage and warehouse space to optimize labor costs and maintain cost efficiency. Wearable tech and VR training help you improve workplace safety and employee satisfaction, while sustainable practices will establish you as a business that cares.

About The Author

Alina Kostukova

Skilled marketing content creator with a background in digital media and public relations. Focused on creating first-rate text and visual content that stands out and tells compelling stories.