- Best Practices

- Industries

How to Use Data to Improve Wholesale Logistics

by

Mike Foster

April 17, 2024

If you’re a company dealing in the wholesale market, utilize every resource available to you. This will significantly improve the company's overall logistics. Not only that, it will help you manage and store your goods in a better way.

Logistics analytics is vital for any business to improve. The analytics use data from shipments, routes, and delivery operations. Companies can optimize routing with this data and predict delivery times more accurately.

“According to Databrain, logistics inefficiencies consume up to 28% of logistics operating costs. However, the companies that used data analytics had improved customer satisfaction, more effective routes, and significant cost reductions.”

Data analytics enhances delivery efficiency significantly. It is crucial for route optimization and supply chain management. With detailed insights from old and new data, businesses in the wholesale sector can improve and grow. They can become more competitive and efficient.

Jump to the most relevant part:

Now, let’s take a detailed look at how all of this unfolds.

The evolving role of data analytics in wholesale logistics

The way organizations manage their supply chains and logistics is changing. The wholesale industry is seeing significant improvements with big data, AI, and machine learning. These include better efficiency, more transparency, and more intelligent decision-making.

Big data in wholesale logistics

Big data is the massive amount of data that businesses collect daily. For someone like you in the wholesale logistics sector, big data analytics is an important fact. It helps in understanding ongoing trends in the market, what customers want, and how much inventory is available.

By analyzing this data, you, as a wholesaler, can predict demand, optimize inventory levels, and reduce waste. This precision in forecasting helps in minimizing overstocking or stockouts.

Artificial intelligence and machine learning

AI and ML technologies are changing the game for data analytics in the wholesale logistics world. They make it possible to automate complicated decisions, leading to quicker and more accurate reactions to changes in the market.

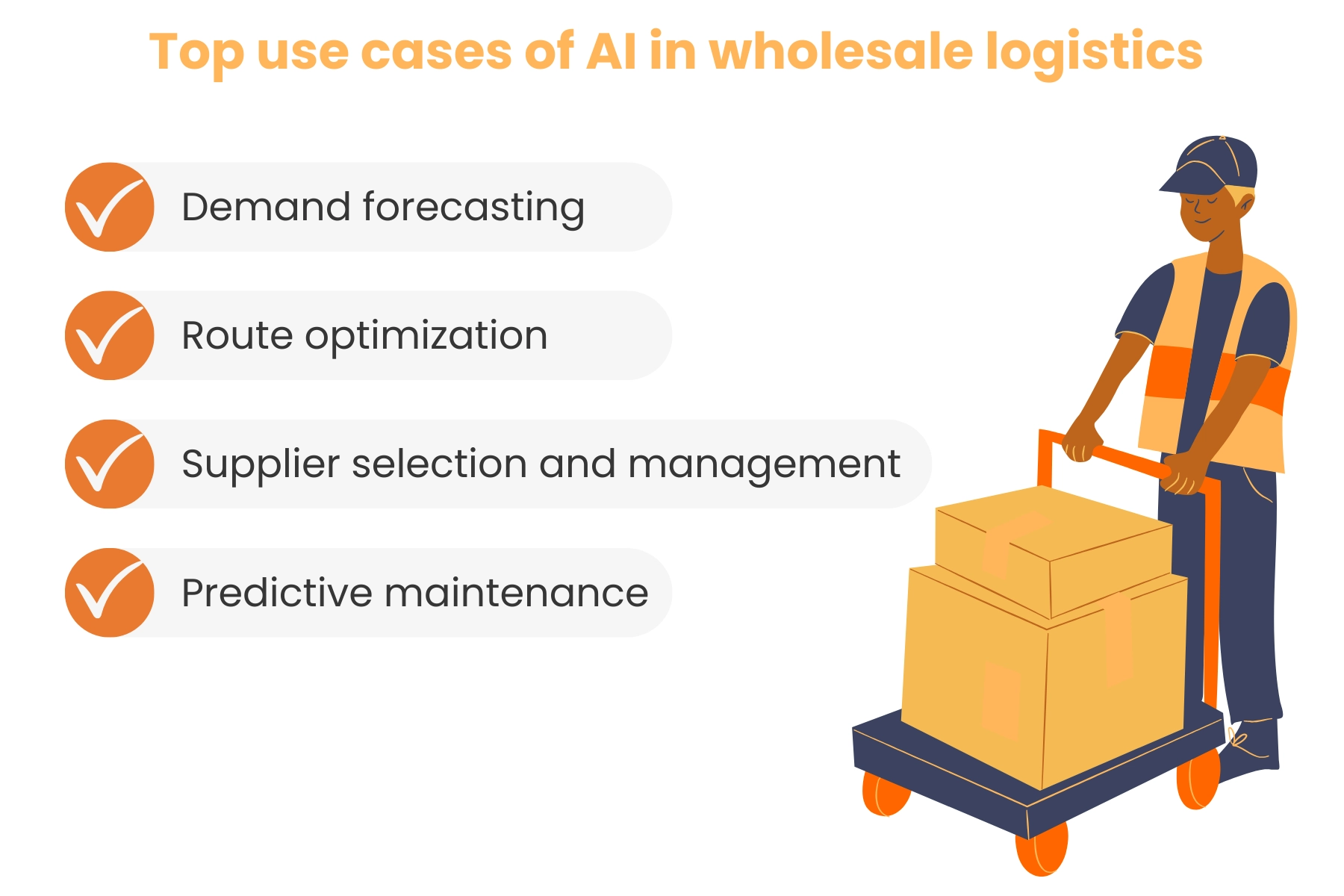

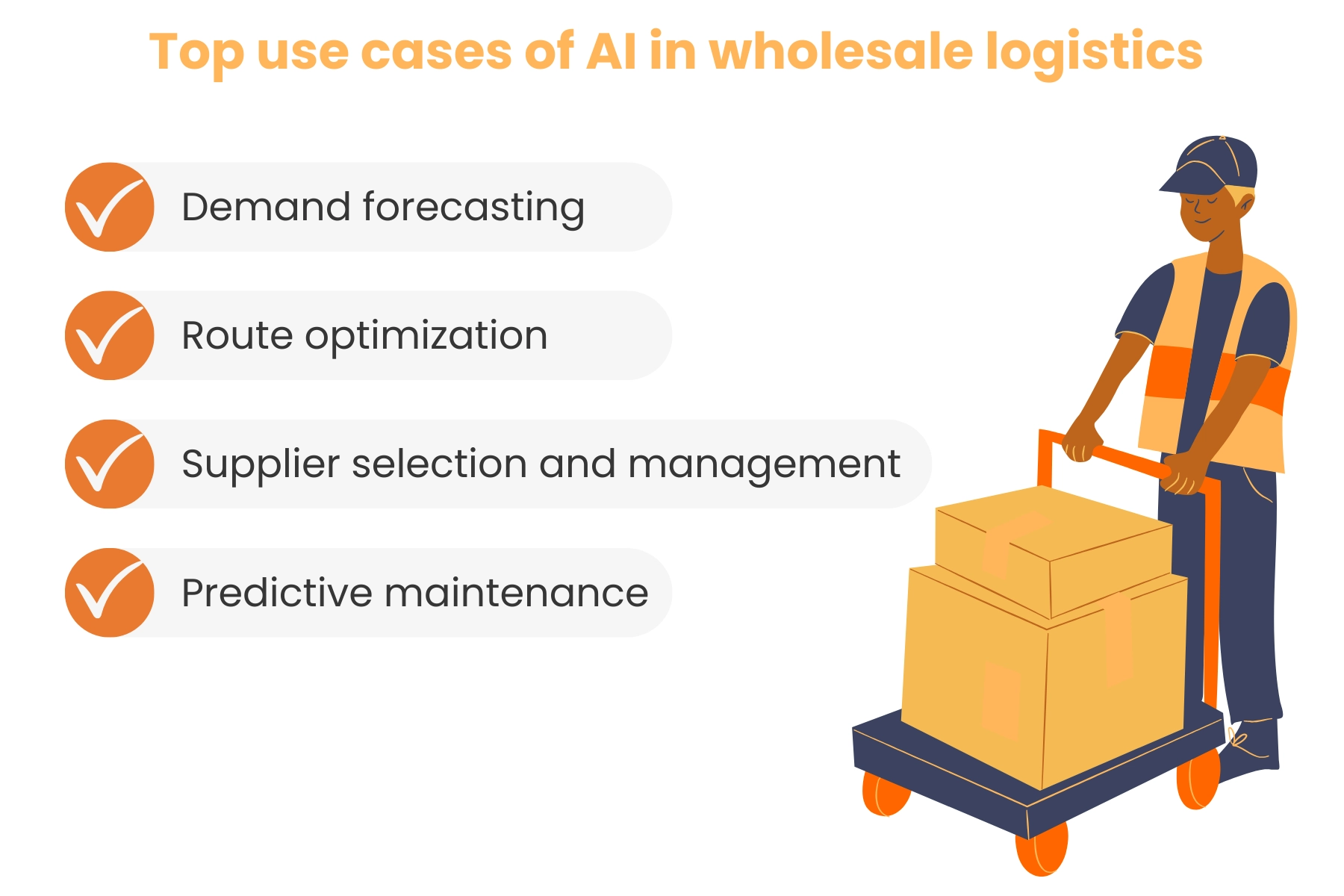

Here are some key ways they're being used:

- Demand forecasting: AI algorithms are designed to predict future demand. They look at past sales, market trends, and other essential factors to make it happen. This helps keep the right amount of stock, reduce costs, and make customers happier.

- Route optimization: AI and ML examine traffic, weather, and delivery schedules to find the best delivery paths. This means less fuel used, quicker deliveries, and less pollution.

- Supplier selection and management: AI evaluates how healthy suppliers are doing to help wholesalers pick the best ones and keep good relationships with them.

- Predictive maintenance: AI tools can foresee any breakdowns, They use past maintenance records and how machines are currently performing to do this. You can also use this approach to avoid expensive interruptions and make necessary equipment last longer.

The impact on supply chain management

In the rapidly evolving supply chain management landscape, the infusion of data analytics has emerged as a game-changer, transforming how businesses approach logistics and operations.

Let's delve into how these technological advancements have revolutionized supply chain dynamics, leading to unparalleled levels of efficiency, strategic insight, and collaboration.

- Enhanced transparency: Modern route planning software solutions, such as Track-POD, offer a clear view of the supply chain as things happen. This allows for better teamwork and quick responses to any problems.

- Improved efficiency: Mistakes and costs go down by automating regular tasks and improving logistics operations. This makes the whole operation run more smoothly.

- Strategic decision making: Using data to make decisions helps companies choose more innovative strategies. They can match their supply chain and logistics plans with the market's wants and the chances out there.

Benefits of data analytics in wholesale logistics

Harnessing the power of data analytics in wholesale logistics streamlines operations and sets the stage for significant advancements in customer service, cost efficiency, and strategic positioning. Here's an in-depth look at the transformative impact of leveraging data to optimize the wholesale logistics sector:

Cost reduction and inventory optimization

Data analytics helps find and fix problems in how goods are stored and moved. By looking at information on how much fuel is used, how often vehicles need fixing, and how long deliveries take, businesses can make better plans for how to move goods. This means they can choose the best paths and reduce waiting times. This approach saves money and makes the whole process of moving goods more efficient.

Improved customer service

Another benefit of using data analytics is improved customer service. The information businesses gather from the data allows them to customize their products, make delivery faster, and communicate better. When the customers get what they want or even more, they become loyal buyers and even recommend you to others.

Competitive advantage

Data analytics can help businesses make more intelligent choices. There are still many companies that rely on old methods of managing things. This is good because even if you use the slightest of data analytics tools, you’ll have a competitive advantage.

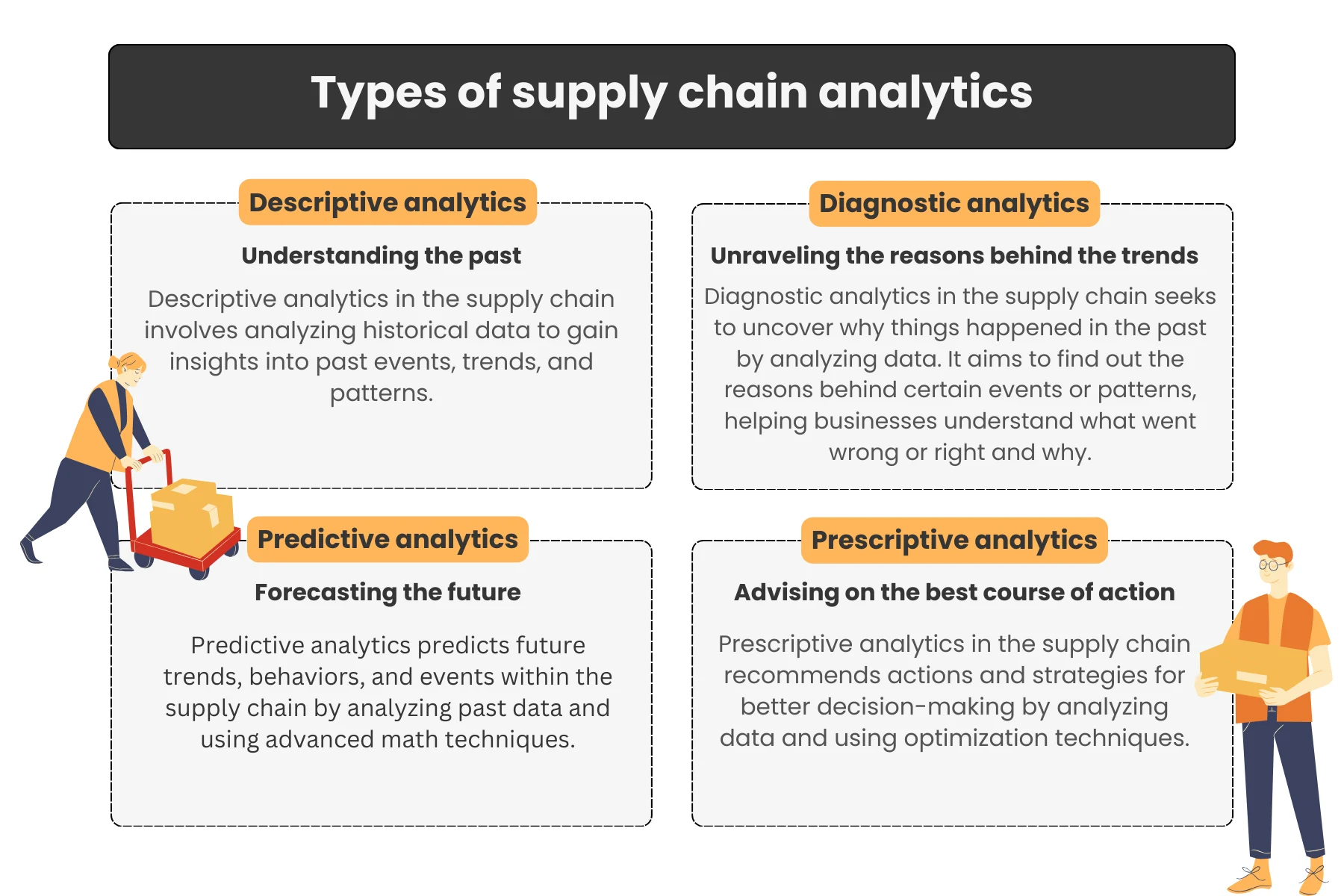

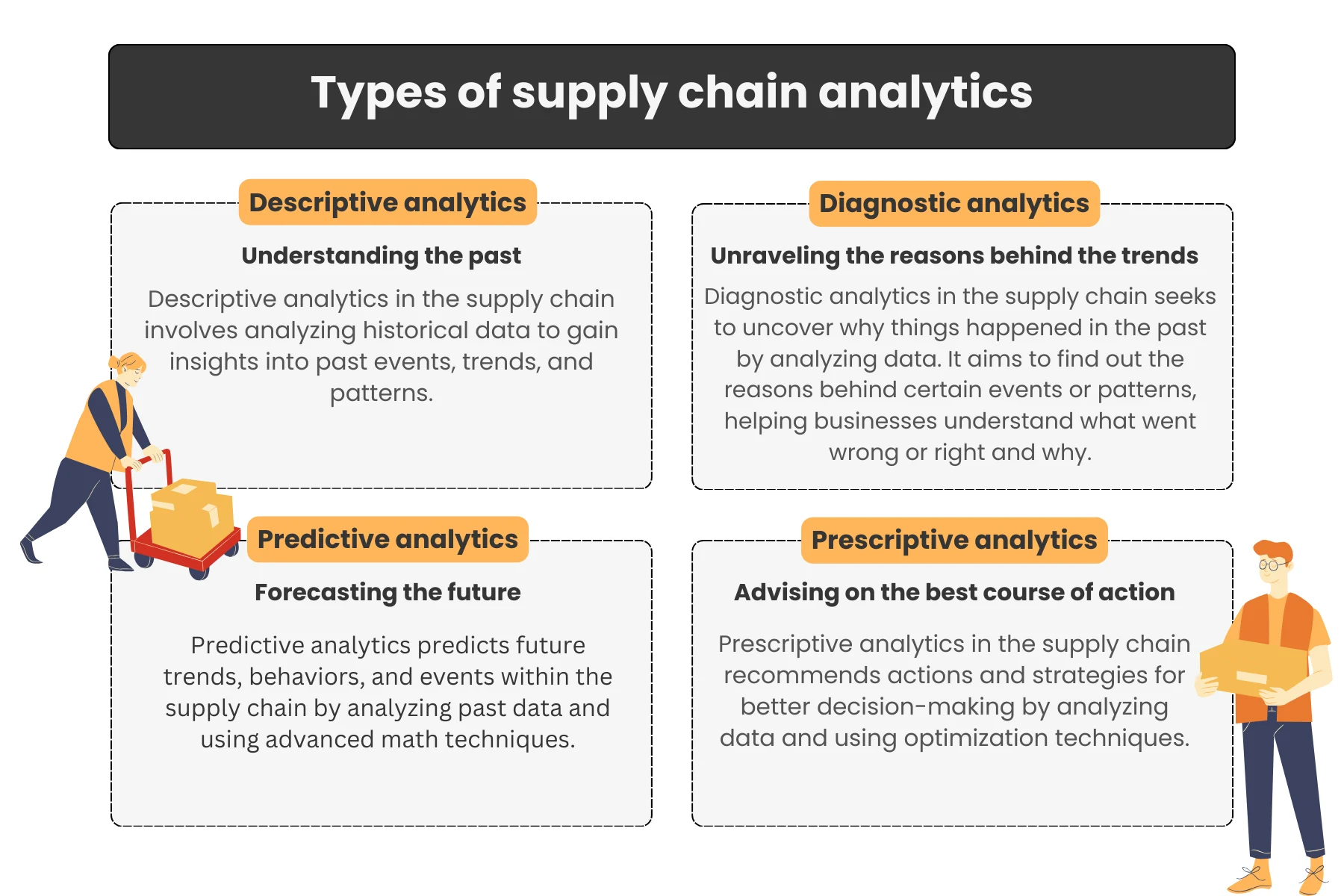

Types of supply chain analytics

Supply chain analytics transform the vast amounts of data the wholesale industry generates. Let’s look at the four main supply chain analytics types.

1. Descriptive analytics: understanding the past

Descriptive analytics helps you understand past events in the supply chain. It looks at old data to find trends, patterns, and unusual events.

For a wholesale distributor, it can show what has been sold, how much stock was kept, and what customers wanted before. Looking at these past events, a wholesaler can see when people buy the most, which products are favorites, and how fast products are selling.

This basic analysis gives wholesalers a clear picture of how their business is doing. It shows what works well and what doesn't. It's the first step in analyzing data that helps companies to predict what they might need in the future based on what happened before.

2. Diagnostic analytics: unraveling the reasons behind the trends

Diagnostic analytics is like being a detective with numbers. It doesn't just see patterns; it tries to discover why stuff is happening. You use special tools to look at the numbers closely, find patterns, and see how different pieces of info fit together.

For example, if fewer folks are buying a sure thing, diagnostic analytics can help determine why. Maybe the store needed more, the thing got worse, or folks started liking something else more.

Understanding these reasons helps shops know exactly how to fix stuff or make the most of good stuff. It's all about digging deep to make smart changes.

3. Predictive analytics: forecasting the future

Predictive analytics is like peeking into a crystal ball using old data to guess what might come next. It's all about using fancy math and tricks to predict future trends and actions.

For wholesalers, it's super handy. It can guess how much of a product they'll need. This means they can keep the right amount in stock, not too much or too little. It looks at what's sold before, seasonal stuff, and what's up in the market to make these guesses.

Thanks to predictive analytics, wholesalers can plan. They can save money and keep customers smiling by managing their stuff better. This way of looking forward helps them prepare for what's coming and change how they do things to match what they think will happen next.

4. Prescriptive analytics: advising on the best course of action

Prescriptive analytics is like having a super intelligent advisor who doesn't just predict the future but also tells you what to do about it. It uses fancy math and machine learning to offer suggestions and show what might happen if you follow them.

For instance, if predictive analytics says more folks will want a thing, prescriptive analytics can tell you exactly how much more to make. It ensures you meet demand in a timely manner. It can even suggest the best shipping methods to save time and cash.

This type of analytics gives wholesalers clear guidance on improving their game and raking in more dough. It helps make wise choices by showing what could go down with different options. This way, businesses can tackle tricky problems and stay ahead in the market.

Application of big data analytics in supply chain

Key applications of Big Data Analytics in Supply Chain include:

- Sales, inventory, and operations planning:

Companies use lots of different data to plan better. They can see what customers want in real time, just like managing a power grid. They can quickly fix it if they have too much or too little of something. This keeps everything running smoothly.

- Predictive maintenance and intelligent workload optimization:

Smart factories produce lots of data. Companies can use AI and machine learning to predict when machines will break down. They can also plan work more efficiently. This makes the whole operation run better.

- Demand forecasting and delivery prediction: Big data helps companies guess what customers will want in the future. They can also figure out when deliveries will arrive. This helps keep costs down and avoids problems with needing more stock.

Real-world case studies of big data analytics in supply chain

1. A global Fortune 100 engineering company

The company faced problems with its internal logistics platform. The platform needed to be more efficient and support its global warehouse network. The company decided to partner with specialists. Their goal was to modernize the platform. They used microservices, DevOps practices, and Computer Vision solutions.

This upgrade automated many manual tasks. It also streamlined inventory management. The company has over 400 warehouses worldwide. Thanks to these changes, the company's internal logistics efficiency improved significantly.

2. A Fortune 500 industrial supply company

The company was having a hard time as it had to handle a lot of data to keep inventory costs in check. They set up a single, cloud-based platform for all their big data. This platform brought together information from more than 100 different sources. Thanks to this, the company could predict inventory costs more accurately. They also saved money on infrastructure and managed their data more efficiently.

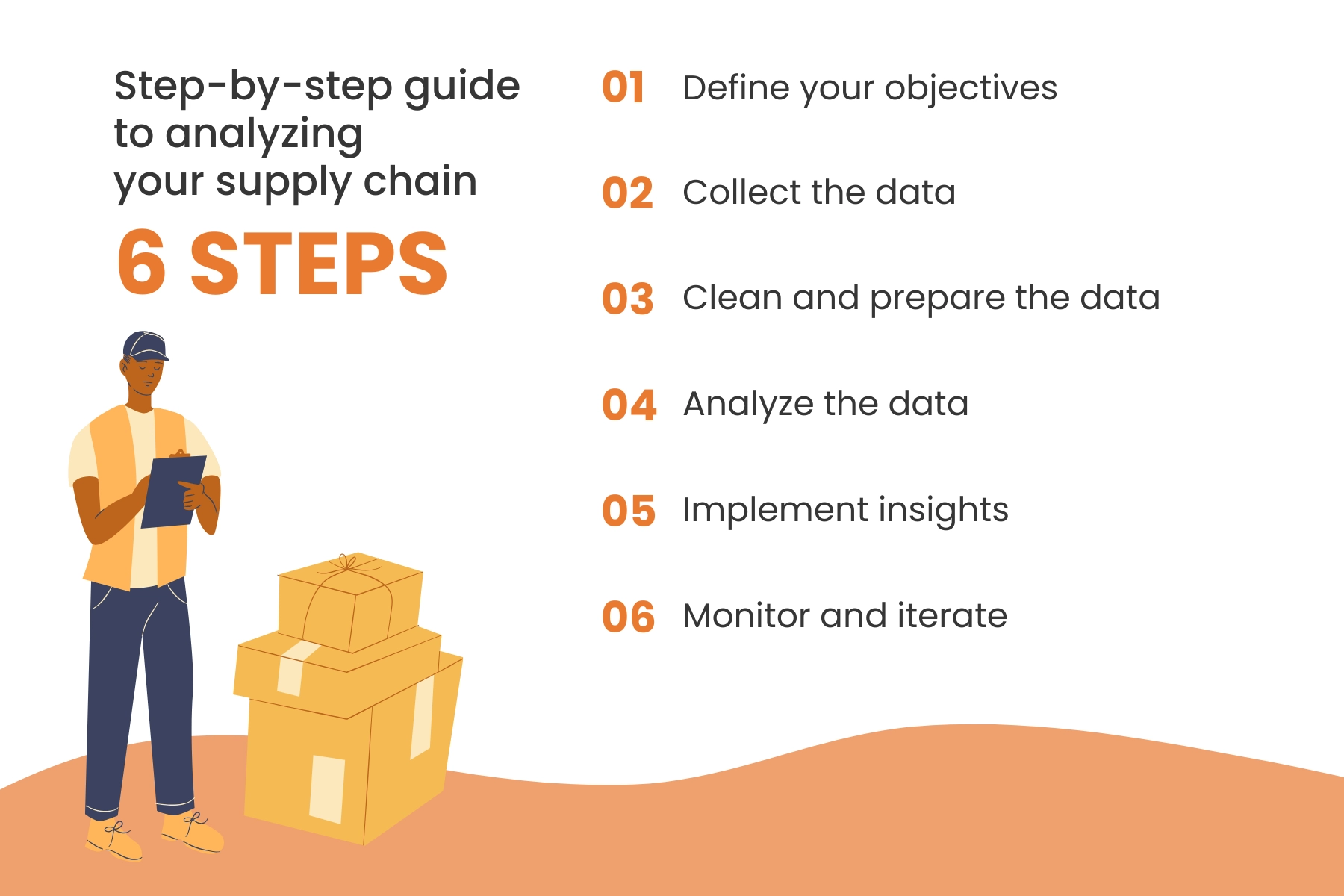

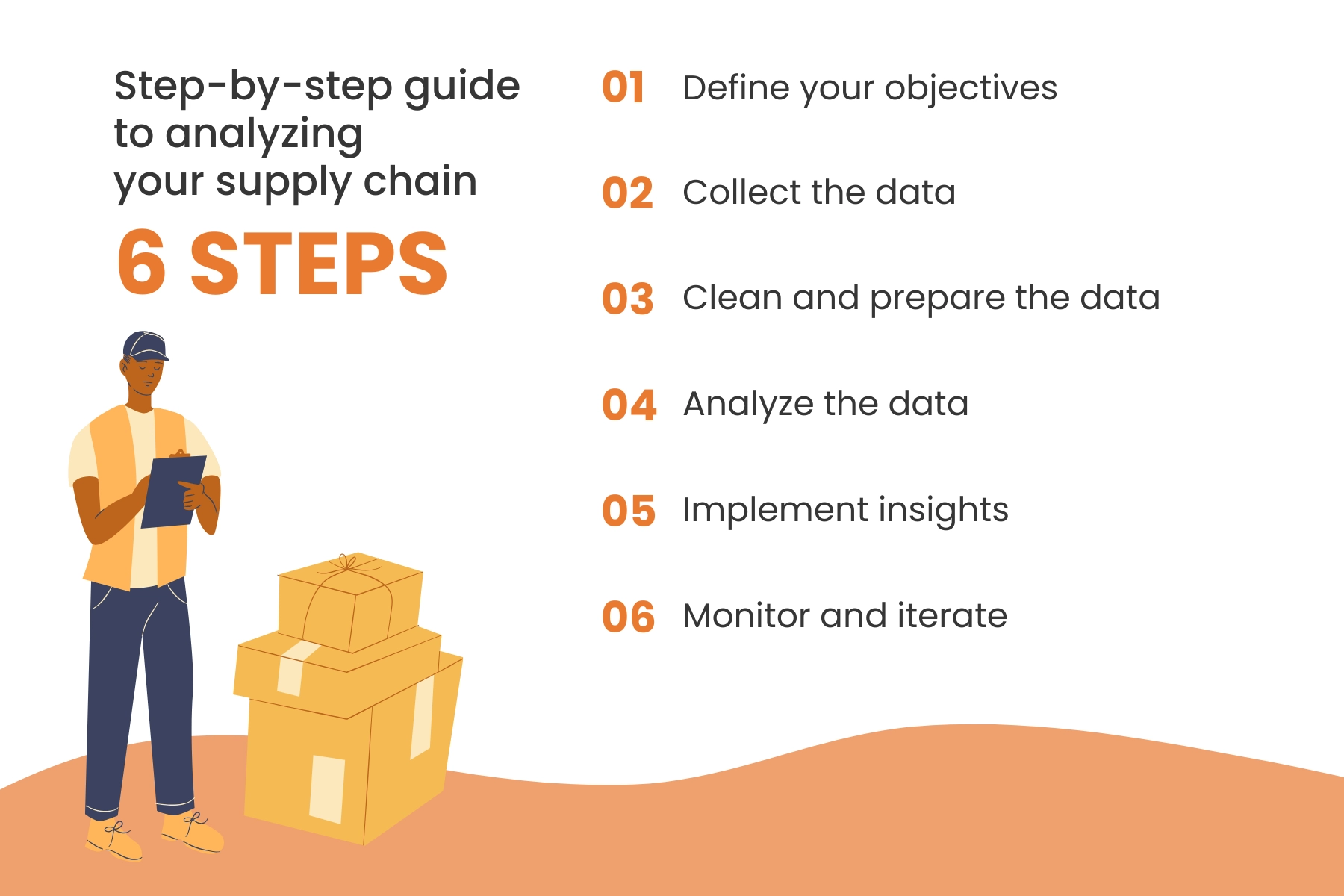

Step-by-step guide to analyzing your supply chain

Implementing data analytics in supply chain analysis can truly transform organizational operations. Here's a guide on how to make the most of data analytics for supply chain analysis, along with practical solutions to common issues:

Step 1: define your objectives

First things first. You need to figure out what you want to achieve with this. Are you looking to spend less money, speed up your deliveries, or optimize your supplies? You don’t have to have one goal; you can have all three as well. However, if you have a clear goal in mind, you’ll be better equipped to make important decisions.

Step 2: data collection

Now, we have the most essential part. You need to gather data from all the levels of your supply chain. Like from suppliers, making stuff, moving it around, and what customers say. The more information you have, the better your analysis will be. Use fancy gadgets like IoT devices, ERP systems, and SCM software to grab data automatically whenever possible.

Challenge: data silos

Solution: implement integrated software solutions that promote data sharing across departments. Encourage a culture of transparency and collaboration to break down silos.

Step 3: data cleaning and preparation

In this step, you need to tidy your data up. As you know, raw data can be messy, with mistakes, repeats, or stuff you don't need. Here, you must use data-cleaning tricks to ensure your dataset is spot-on and good to go. That might mean kicking out weird bits, filling in blanks, or making everything look the same.

Challenge: time-consuming data preparation

Solution: leverage automated data cleaning tools and establish a standardized data entry process to minimize errors at the source.

Step 4: analyze the data

Now, we have the first complex step, where you’ll analyze the data you’ve gathered. Firstly, you need descriptive analytics to understand what's happening currently. After that, use predictive analytics to forecast future trends. Finally, prescriptive analytics can be used to suggest actions to take.

Challenge: complex data analysis

Solution: Invest in training for your team or partner with data analytics experts. Utilize user-friendly analytics platforms that simplify the analysis process.

Step 5: implement insights

Turn your intelligent insights into stuff you can do. Like tweaking how much stuff you keep in stock, finding faster ways to move things around, haggling with suppliers for better deals, or changing when you make stuff.

Challenge: resistance to change

Solution: communicate the benefits and rationale behind changes to all stakeholders. Implement changes gradually and monitor closely to adjust as needed.

Step 6: monitor and iterate

The supply chain is dynamic, so your data analytics approach should be, too. Regularly review your analytics strategy and outcomes. Use real-time data monitoring to adapt quickly to changes in the supply chain environment.

Challenge: keeping pace with changes

Solution: establish a continuous improvement mindset within your organization. Encourage feedback and be prepared to adjust your analytics strategies as the supply chain evolves.

The future of data analytics in wholesale logistics

The future of data analytics looks bright and promising. Data analytics can become the backbone of wholesale logistics. There are so many new things emerging as technology is advancing. Let’s take a look at a few of them.

Real-time data and IoT integration

The very first thing here is the Internet of Things (IoT). It is designed to be a game-changer in logistics data analytics, so you better start using it. Just imagine how IoT gadgets will be available everywhere on the supply chain.

Managers in charge of logistics will get instant data from these gadgets. With this live stream of info, they can make quick decisions. They could change routes, move delivery times around, and update how they manage stuff in stock based on the newest data and what's happening right now.

Blockchain for enhanced transparency and efficiency

Next up is blockchain technology, which can stir up how data analytics is used in logistics. It offers a way to keep a clear, unchangeable record of all transactions and movements in the supply chain. This means the data used for analytics will be much more reliable and trustworthy.

Using blockchain will make it easier to track goods accurately and safely, make contracts automatic, and make operations smoother. All of this can lead to doing things more efficiently and cutting costs.

Autonomous vehicles and drones

Bringing autonomous vehicles and drones into logistics will create new data for analysis. These technologies will change how delivery and transportation work. They'll also give valuable information about the best routes, traffic patterns, and delivery speeds. Logistics companies can improve their operations by looking into this data. They can speed up deliveries and reduce costs.

Conclusion

Using data analytics is very important for the wholesale industry. It helps improve how things are moved and managed. Here are the main points:

- Real-time data lets you make quick decisions.

- Predictive analytics helps guess demand and manage stock.

- Advanced tools give a clear view of the whole supply chain.

If you want your business to grow, start leveraging data analytics. Also, delivery management platforms, such as Track-POD, can help deliver faster and better and improve relationships with suppliers and customers. It saves money and makes operations run smoother.

In simple terms, data analytics is critical to success in the wholesale business. It helps companies stay ahead, adapt quickly, and meet customer needs. By using data wisely, wholesalers can be more efficient and competitive.

About The Author

Mike Foster

A dynamic writer whose passion for technology and Software as a Service (SaaS) is the driving force behind his compelling work.