Checklist for Reducing Overheads in Your Wholesale Business

Updated on

April 11, 2024

by

Andrey Baturin

Managing expenses and operating costs is an essential element of survival in any business. Keeping accurate records, monitoring what you spend, and constantly endeavoring to reduce costs will directly impact your company’s cash flow and profitability.

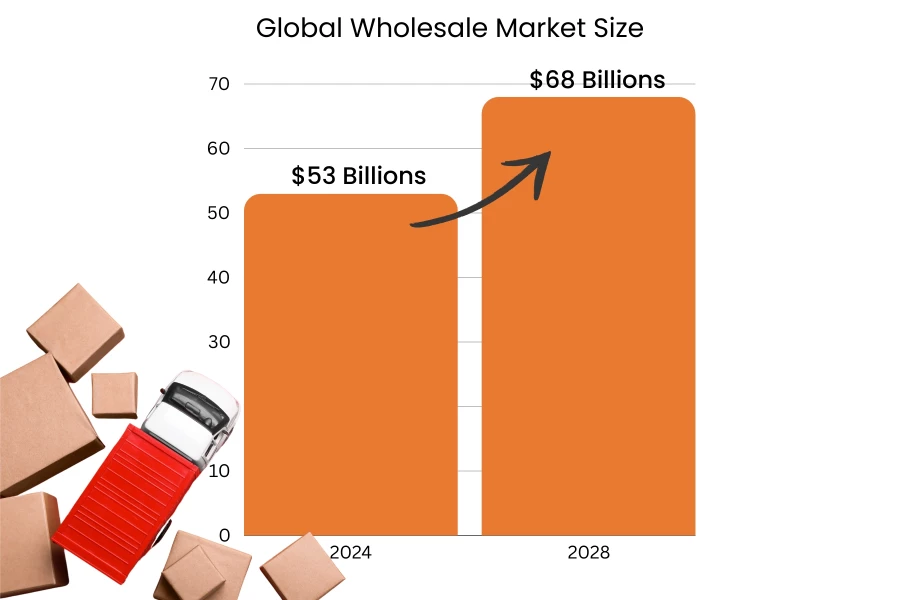

Research suggests strong growth in the wholesale industry in recent years, with a compound annual growth of 7.1 percent in the last year, reaching a staggering $ 53,017 billion by 2026. These figures indicate the competitive nature of wholesale business and the need to strive for excellence in your everyday operations.

In a wholesale business, your major cost centers are likely your stock-holding and logistics. Warehouse space is at a premium and must be managed wisely to optimize your stock levels and boost your profits.

Keeping large quantities of stock costs money and takes up valuable warehouse space. It also increases your risk, insurance coverage, and other overheads.

Products change over time, and so will your client base, so it’s important not to overstock on products that may become redundant or obsolete. Conduct regular assessments of your business model to ensure that you still align with market trends and avoid buying products that will not sell. This is especially relevant in fast-developing environments such as electronics, where products could become redundant in a matter of months.

With the right inventory management tools, you can optimize your stock levels and reduce space requirements within your warehouse. This will enable you to cut down on other overheads such as wages, stationery, and insurance premiums.

Monitor your costs carefully and reduce expenditures where possible.

Understanding your overhead costs

There are apparent costs in the wholesale business: the cost of floor space in your warehouse and your inventory, transportation of stock, and the monthly insurance premiums to cover both warehouse facilities and inventory. There are also other expenses that could be more obvious but that have a significant impact on your profit margins if not correctly managed. Here are some of them:

- Staff salaries and wages.

- Purchasing and maintaining equipment such as forklifts and shelving.

- Safety equipment for workers: helmets, boots, and overalls.

- Electronic equipment: barcode scanners, printers, and monitors.

- Labels and stationery.

- Lighting and heating.

- Stock redundancy.

Effective management of these business areas will keep the business running smoothly and inevitably save you money.

Regular stock takes are essential to identify stock losses due to inefficiency or theft and to remedy the problems before they escalate.

Process audits should also be undertaken regularly to identify and remedy any gaps or bottlenecks in the operational processes. To begin with, monthly or quarterly audits may be necessary, depending on the complexity of your operations. Once your business has settled, a bi-annual or annual audit should be sufficient.

Our top cost-cutting tips for wholesalers

The more products you have in your warehouse, the more space and resources you need. We will give you some ideas on reducing inventory costs and streamlining your ordering process.

To get an idea of how much your warehouse space costs, do an exercise based on the number of products stored per square foot and administrative, operational, and human resource usage broken down into cost per square foot. You will be amazed at how much you can save by minimizing your square footage requirements.

Effective wholesale inventory cost-saving methods include the following:

Accurate forecasting to avoid overstocking

Holding large quantities of high-value items without having firm orders for the stock simply does not make sense. At the same time, you don’t want to run out of stock, which will encourage customers to take their business elsewhere.

It’s easy to overstock when you are eager to meet customer demands and not run short of products to sell. It also happens when items are in short supply; the tendency is to buy extra stock to see you through the lean times, but it often results in excessive products that are difficult to sell.

Overstocking costs money and, in the long run, will force you to increase prices to meet your warehousing overheads.

The key to avoiding overstocking is a thorough market analysis and accurate sales and inventory forecasting. Based on historical sales and product information, you can predict patterns and changing trends in product demand and reduce your stock, keeping it to a minimum.

Inventory management

By conducting a thorough analysis of your stock and constantly managing your stock levels, you can avoid overstocking while still having enough to supply customers when needed.

Computerized inventory systems will issue a warning when you exceed the maximum or minimum stock levels that you have prescribed. They also enable you to build safety stock levels per stock item to ensure sufficient stock without overstocking.

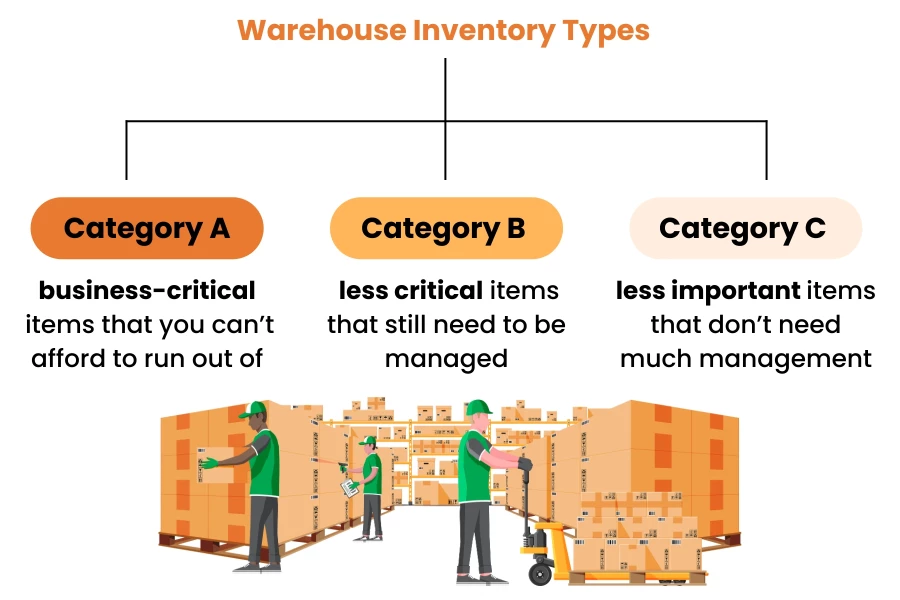

Categorization of inventory types gives you greater control over your stock. This can help you identify your inventory by product type, fast-moving stock, or high-value items.

A popular method of categorization is the ABC method:

Category A and B items can be prioritized for more frequent stock takes and a more in-depth focus on safety levels and order quantities.

Eliminate excess stock

At some point, the stock becomes more expensive to keep than what it is worth if you were to sell it. If you have chosen to categorize your items into A, B, and C categories, this is where you can focus on category C to determine which products to eliminate. Inventory reduction examples include:

- Identify the slow-moving products in your inventory and do some analysis as to why they don’t sell.

- Run a promotion on the slow-moving products and offer significant discounts.

- Consider bundling similar products, such as back-to-school packs that include stationery, and add a slow mover to the bundle.

- Try selling old stock to clearance retailers; if that fails, scrap it or donate it to a worthy cause.

Implement a redundancy process to liquidate stock that is not moving, as this will reduce warehouse costs and free up space for more profitable items.

Establish relationships with suppliers and customers

Establish relationships with suppliers and communicate your anticipated needs so that they are prepared to let you have the stock when needed.

Some suppliers will take back redundant stock at a reduced price. This is not ideal, but it is better than holding on to a stock that is not likely to move.

Establish relationships with customers to understand how much stock you will need to provide in the future.

Being able to categorize stock and identify what is selling, whether the markets are shifting, and forecasting what you will need in the near future will enable you to cut down on excessive stock that you won’t be able to sell.

Leverage technology such as data analytics to help you analyze your sales and forecast future inventory requirements.

Automated lifters, pickers, and conveyor belts are some of the many tools you should consider in your quest for improved efficiency in the warehouse. This equipment involves an expensive outlay, but in terms of efficiency, it will pay for itself in time and give you more control over the inventory processes.

Distribution of your sales

A large percentage of costs in a wholesale business lie in the distribution of your products.

Depending on the size of your operation, you will have at least one or two delivery vehicles that require fuel, maintenance, and insurance coverage. Add drivers’ wages into the equation and include time lost due to unforeseen traffic incidents or other delays.

How do you reduce the cost of distribution?

Optimization of your fleet management and delivery processes is essential if you are to cut costs and keep your customers happy.

First, calculate your delivery costs to see how much they affect your profit margins.

- Efficient route planning will enable you to cut down on fuel consumption and time, allowing you to increase the number of deliveries made in a day.

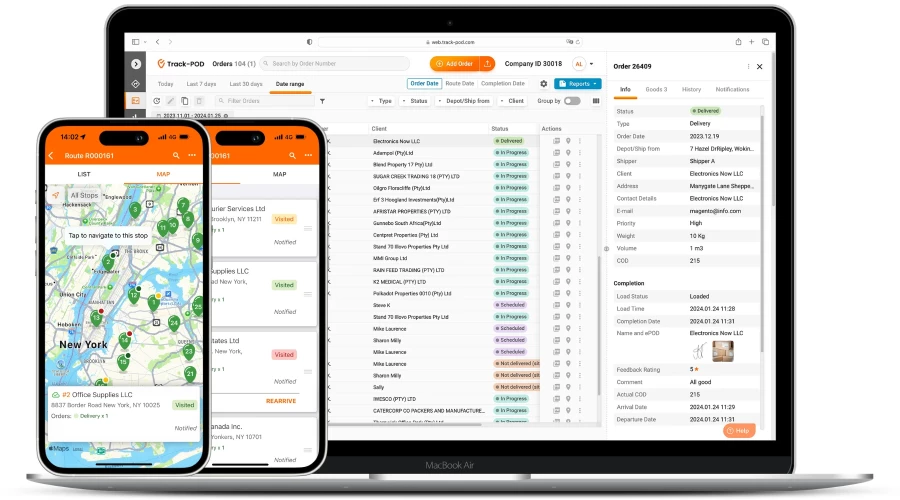

- If you leverage last mile delivery software like Track-POD, you will be able to install delivery driver apps on your driver smartphones to have real-time tracking of their activity, making sure your deliveries are reaching their destinations on time.

- Implement a regular vehicle maintenance routine to maintain your vehicles in good running condition. This will save repair costs in the long run, improve fuel efficiency, and avoid expensive breakdowns.

If this sounds like a lot of additional costs and involves expertise you don’t currently have, consider investing in route planning software. Automating your route planning process will save vast amounts of time and resources, optimize the use of your vehicles, speed up your deliveries, save fuel and maintenance costs, and keep your customers happy.

How do you cut costs in the supply chain?

The term “supply chain” encompasses the entire process of producing and selling products and the individuals and companies involved. From acquiring raw materials through the manufacturing process to dropping the final products off at the customer’s premises, the success of this dynamic network is crucial to your wholesale business.

Supply chain management in the wholesale business includes:

- Identifying the demand for products

- Methods of supplying the products to wholesalers, retailers, and end users.

- Inventory planning, including the use of forecasts for adequate stock holding.

- Capacity planning to determine the levels of personnel and equipment required.

- Distribution management to ensure the safe transport of goods and drivers.

Sales and inventory managers use historical data to forecast sales and stock usage. Still, sudden, unexpected shortages of raw materials or finished goods can dramatically affect your operation. Forecasting software comes with ‘what-if’ scenarios for more effective planning.

Collaboration between companies across the supply chain means managers are better positioned to predict end-user requirements and adjust when unforeseen events occur.

The ultimate goal would be sharing real-time data between the different entities involved in the supply chain, empowering all stakeholders to forecast and deliver their part of the deal accurately. This level of collaboration is available with the innovative technologies that exist today.

Lean supply chain management strategies include eliminating redundant stock and incorporating strict measures in the procurement system.

An ideal strategy in the wholesale business is just-in-time (JIT) ordering, where an order for stock is only placed on the supplier once a firm customer order has been received.

Save time and enhance efficiency by automating sales and inventory forecasting, procurements, and delivery routes.

Leveraging technology for cost reduction

In a wholesale environment, you ideally need a software system that takes care of your entire business operation on one platform. When it comes to logistics, however, it is more likely that you will find a separate logistics solution that offers comprehensive logistical functionality and integrates with your ERP and CRM systems in real-time, providing electronic delivery notifications, information regarding products shipped, and incorporates the logistical costs into your financial system.

In larger warehouse environments, everything can be automated, from packing, picking, and retrieving stock items to barcode scanning and printing, labeling of stock, and stock counts.

Some of the latest warehousing trends include:

- 3D bin packing helps you weigh your stock and select the correct box size, saving on packaging costs and speeding up the packing process.

- Robotics technology can assist with packing, opening, filling, labeling, bar coding, and palletizing stock items.

- Automated forklift trucks and drones pack, pick, and retrieve stock from the shelves.

- Integration with your ERP system and real-time recording of each transaction as it happens.

These technological improvements eliminate human intervention, increase accuracy, and speed up your processes.

When it comes to transporting your products, optimizing your vehicle routes will significantly impact your logistical processes and costs, and the resulting improvements in delivery times will undeniably improve customer satisfaction.

A good example of a comprehensive logistical solution is Track-POD’s web-based route planning software’s transport management system (TMS).

The TMS system enables you to keep track of all supply chain events in real-time and integrates with your ERP, CRM, and warehouse management systems (WMS). The Track-PODs transport management solution enables your management team to communicate with all stakeholders in the supply chain process, bringing the data together in one place to facilitate faster and more accurate business decisions.

Track-POD’s TMS facilitates cloud-based data storage, making it available for retrieval when needed. The freight-tracking features empower you to keep track of multiple loads and carriers, giving you real-time freight information at any given time. Integration with many of the ERP and CRM platforms is easy, and many flexible reports are available with a few clicks of a mouse.

Watch your shipment progress with real-time tracking and eliminate tedious manual documentation with Track-POD’s digital shipping documents and electronic proof of delivery (ePOD).

In a nutshell

As seen above, reducing warehouse and supply chain costs is an essential strategy for a successful wholesale operation. Understand and manage your overheads, monitor stock levels closely, and have a stringent redundancy policy.

Good communication with suppliers and customers will foster strong business relationships and increase efficiency in all supply chain sectors.

In addition to the cost-saving and inventory management tips above, there are other business strategies that should be noticed. Invest in the right staff and strive to keep them, as continuity of proficiency and skills is key to successful operations.

A well-structured budget will help you keep an eye on your warehouse costs and processes, and a sound marketing strategy to bring in sales is the ultimate solution to removing stock on your shelves.

And above all, embrace a prosperous future with the automation of your business-critical processes in the warehousing and logistical environment. You might like to take advantage of Track-POD’s free trial offer to check out the platform’s route planning, order management and TMS features.