What Is Fleet Optimization & How to Use It to the Max

by

Yulia Miashkova

October 20, 2022

You have 5 vehicles, 5 drivers, and 50 orders to deliver to customers on a daily basis. Sounds simple, right? Except one vehicle needs maintenance, one vehicle doesn't fit into road restrictions in the area, and orders are of different sizes and volumes.

How do you know which packages need to go into which trucks? How do you run efficient maintenance to minimize downtime? How do you make sure all vehicle resources are used efficiently and every route packs the maximum number of packages?

The answer is fleet optimization.

In this article, we take a close look at fleet management and optimization. What are they and what's the difference? Why do it? And how to do it right? Read on to find out.

What is fleet management?

Let's start with the basics.

Fleet management refers to overseeing all vehicles in a commercial fleet to optimize delivery and improve performance while cutting costs.

Companies with a large commercial fleet often have full-time fleet managers on board. These are the people in charge of all company trucks - management and maintenance.

Fleet managers ensure compliance with safety protocols, control and optimize dispatching, track driver performance, manage fuel consumption, handle customer communication, and participate in the company's planning and other operational activities meant to optimize resources and cut costs.

As you can see, there's a lot that goes into fleet management. Let's see what fleet optimization is.

What is fleet optimization?

Fleet optimization is a build-up on fleet management.

In addition to monitoring and managing vehicles in commercial fleets, optimization tools help managers automate routine processes and make the most of fleet resources.

This includes planning routes that pack the most orders and require minimum driver time, making sure the fleet is used to its top capacity.

This also includes automating equipment maintenance and using data to minimize truck downtime. All in all, fleet optimization is about finding solutions that minimize operational costs and improve fleet performance with the right technology.

Let's look at what you gain when you bring optimization to your fleet operations.

Benefits of fleet optimization

Fleet management and optimization come with a lot of benefits when done right. Below are the most common examples of such perks.

Minimum truck downtime

Fleet management starts with fleet maintenance. A big part of managing fleet operations is making sure all vehicles in the fleet are operational when they're needed.

While some fleet maintenance requires the support of mechanics - and such services should be scheduled - proactive maintenance can be actually delegated to delivery drivers (more on that later)

The driver is the person whose safety depends on the vehicle's condition. They're also the people who spend the most time in the vehicle and therefore have first-hand knowledge of performance at all times.

Cheaper & shorter routes

How do you reduce the cost per delivery? You search for ways to deliver more in a shorter amount of time, with fewer driver resources.

Fleet management solutions, being a part of larger transportation management software, are built to use your every vehicle asset to the max. By matching vehicle specifications to cargo requirements, the smart mobility system will make sure no vehicle space is wasted.

First, all truck and road restrictions are considered. Then, the load is assigned to respective vehicles and drivers. Then, each route is planned in a way that requires the least fuel and driver time. The result: you get closer and closer to providing free delivery.

Fuel management

Fuel management is a natural extension of fleet management and route optimization. Shorter, more efficient routes that pack maximum load result in more efficient fuel consumption.

Because fuel constitutes a big chunk of fleet-related expenses, finding ways to optimize fuel usage and manage key resources better will always be a part of measures to cut transportation and logistics costs.

Fewer driver hours

Fewer driver hours is another example of the benefits you get with fleet management and optimization. When you use technology like AI to optimize your truck resources, you can be sure that your routes and loads are as efficient as they can be.

What that means is you get to create fewer routes that require less driver time. With a constant driver shortage in the transportation and logistics industry, fleet optimization is how you automate truck driver management.

Improved tracking

Tracking data is how a business can get accurate insights into all services and processes. When it comes to fleet management, tracking goes two ways.

One way is the actual real-time tracking of the drivers and trucks' location at all times. For excellent customer experience, GPS tracking in real-time should be available to all parties - dispatchers and customers alike.

Another way to look at tracking is analytics and performance insights. Any transport management software solution will have a smart way to fetch this kind of data to make better optimization decisions.

Fleet optimization with Track-POD in 3 steps

If you're a logistics company or any company that provides the delivery service in-house, you need fleet management and optimization. The best part is that it's easy to set up when you have transportation technology in place.

Let's see how you can optimize your routes and your fleet with Track-POD last-mile delivery software.

1. Add vehicle and drivers data

To get started with route optimization, you need to add your vehicles to the system. You can add three types of vehicles in Track-POD.

- Truck/car.

- Motorcycle.

- Bicycle.

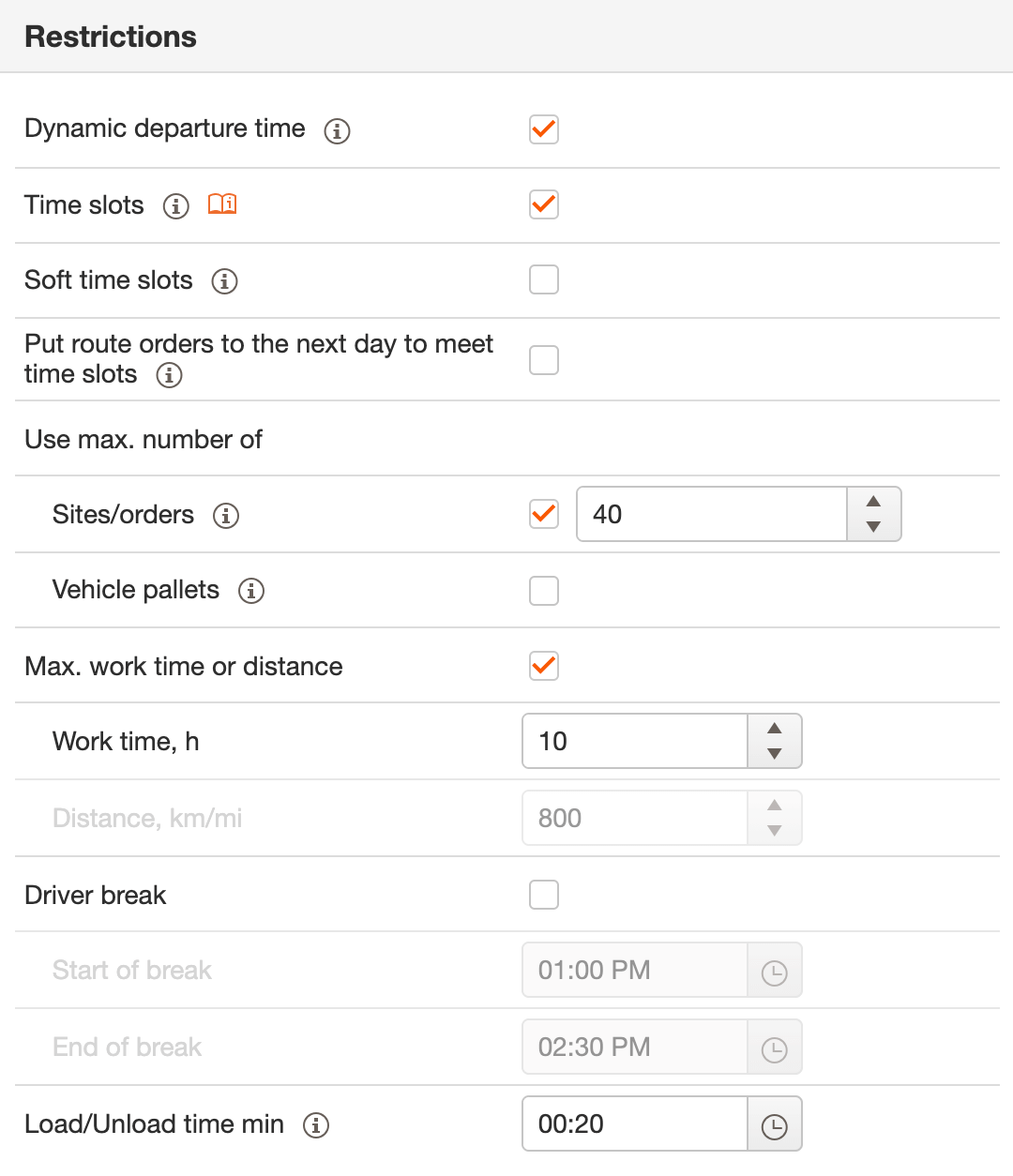

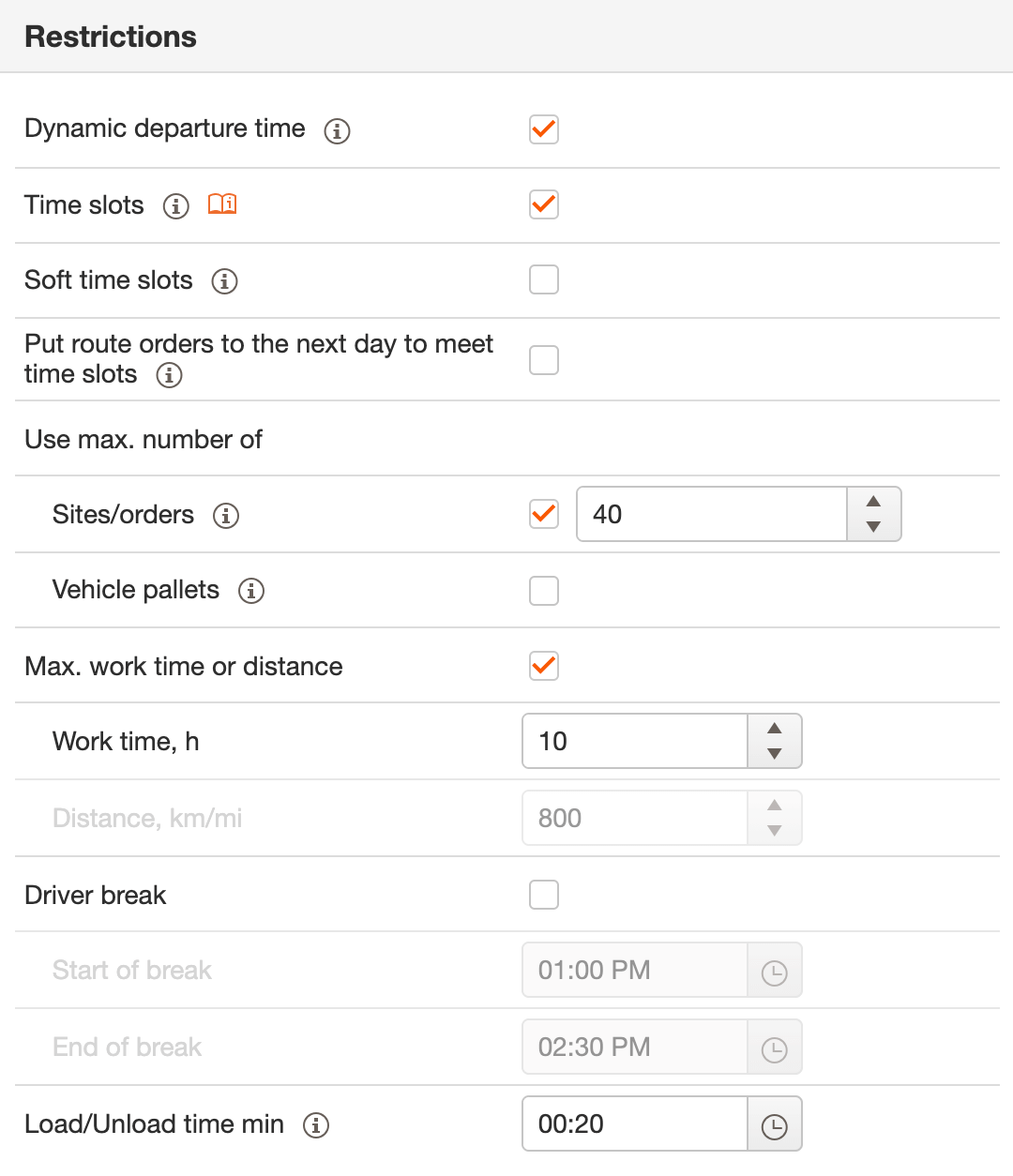

Once you have your trucks in the system, you can choose your route optimization strategy, as well as specify route rates and any restrictions like maximum number of sites/orders, number of pallets, and even driver breaks.

Based on this data, Track-POD will use its route planning tools to create cost-efficient routes using minimum vehicle and driver resources. The routes will then be dispatched to your drivers working on that day.

2. Configure maintenance routine

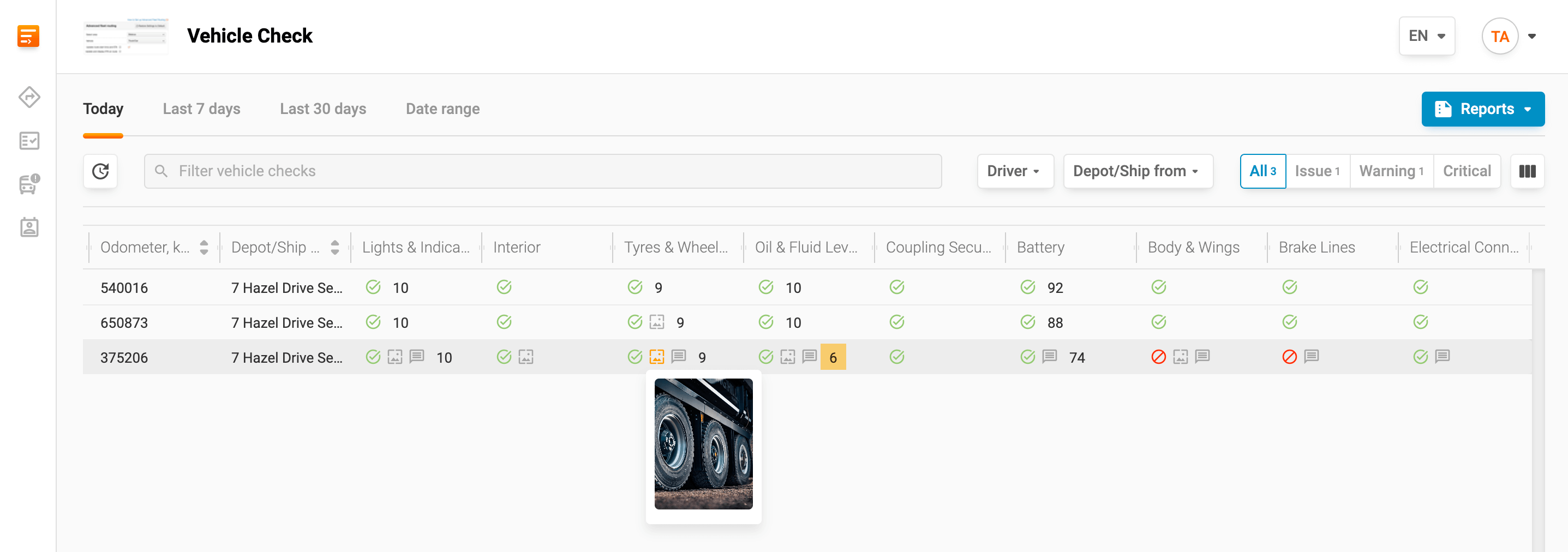

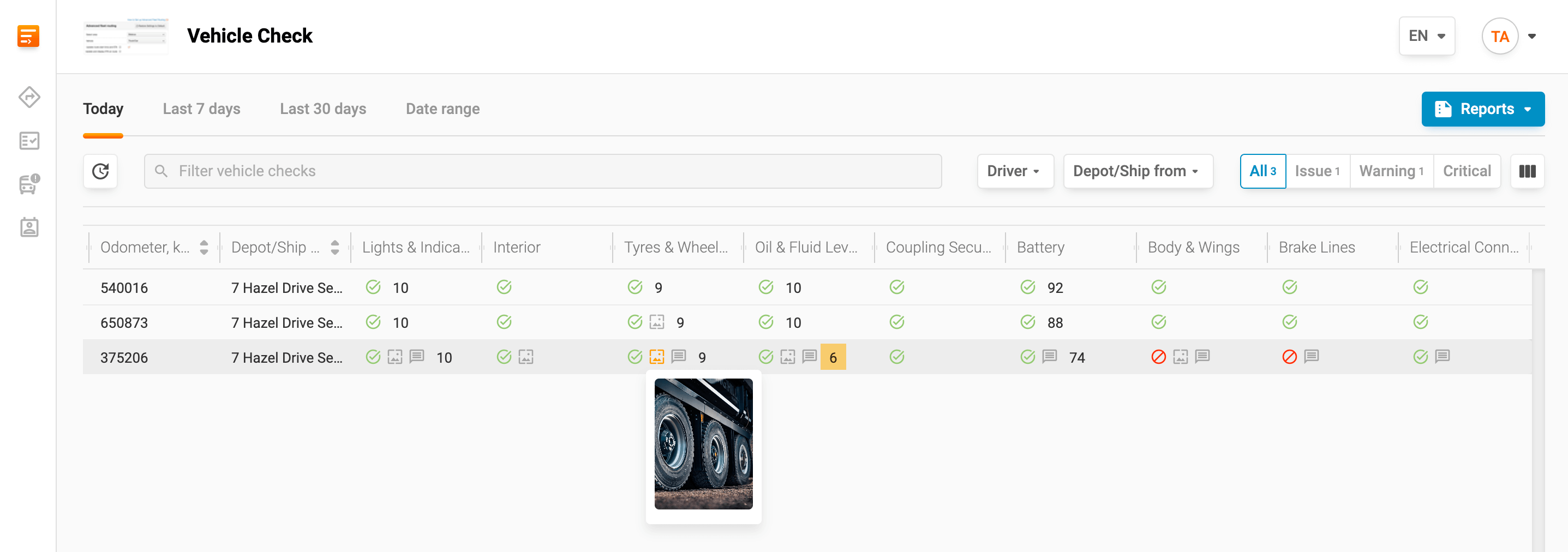

Track-POD route optimization software comes in two parts: a web dashboard for dispatchers and a mobile app for drivers. These provide all the tools you need to ensure safety compliance and set up a maintenance schedule integrated into your drivers' daily routine.

Using the mobile app, your couriers can conduct daily maintenance before and/or after each route. The checklist is configurable on your side and you can choose what the drivers will be reporting on.

Once in the system, all data will be reflected in your web dashboard for easy monitoring of issues that need attention on repair services.

3. Analyze & optimize

A big part of a fleet manager's job is to search for cost-effective solutions for the business. These include reducing company expenses as well as optimizing and planning for a more efficient logistical service.

Luckily, technology is there to support companies with tools that help keep accurate and up-to-date records on fleets efficiency. With automated reporting like Track-POD's, you can access key performance indicators, see data on individual trucks and couriers, and make long-term decisions for the business.

Track-POD makes it easy to draw business insights and find solutions to fleet-related challenges so that you have everything under control.

Wrapping up

Optimizing fleets is an essential part of managing any logistics business. Companies need effective tools and systems in place to make sure all vehicle resources are maintained properly and used to the max.

Track-POD is one of the systems that support logistical operations with reliable fleet management and optimization solutions. If your company needs to improve the efficiency of transportation services, don't hesitate to book a free demo, and let's talk.

About The Author

Yulia Miashkova

Growth marketing manager with a background in public relations, SEO, social listening, and Account-Based Marketing.