7 Functions of Logistics: Roles of Logistics in the Supply Chain

by

Alina Kostukova

July 11, 2023

Logistics is as straightforward as it is complex.

Getting a product or service from A to B is never as simple as that.

Logistics management is intertwined with supply chain management and together, they create complex networks of logistical processes that serve customers.

Because logistics extends far beyond physical distribution, there are multiple roles and functions of logistics. There's a bit of a controversy on how many functions of logistics there are, depending on whether you're grouping similar logistics functions or not.

For the purposes of this guide, we'll be talking about 6 functions of logistics that reflect its role in the supply chain.

Let's dive in.

7 functions of logistics

All logistics operations, regardless of the size of the organization they serve, fulfill certain roles that support the movement of goods or services. Let's see what those roles are and how they all come together in a transportation management process.

The functions of logistics below come in chronological order rather than in order of importance to logistics management. Therefore, transportation and the actual movement of goods come last on the list.

7 functions of logistics

1. Order processing

2. Inventory management

3. Warehousing

4. Packaging

5. Cargo handling

6. Transportation

7. Monitoring

1. Order processing

Any delivery process can only function if there is an order processing system in place.

Order processing systems vary from business to business - from a Shopify store to an ERP. Either way, it's meant to support fast and effective information processing that kick-starts transportation activities.

The key part of order processing in logistics management is integration.

Customer-facing solutions, whatever they are, need to be in perfect sync with the transportation management system (TMS) to make sure the delivery of goods occurs at the right time and meets customer standards.

Setups for processing orders

Here's what order processing can look like, depending on the complexity of the logistics operation.

- Single-click integration for eCommerce (e.g. a WooCommerce store that integrates with a TMS for instant order import).

- CRM and delivery management system integration via Appy Pie Connect or Zapier.

- ERP and TMS integration via API - requires more time and technical involvement.

Whatever the setup, the processing of orders sets the tone for the whole of transportation management: warehousing, distribution, customer service, shipment analytics, and the movement itself.

Pro tip: set up a Zapier integration to connect any order input system (even Google Sheets) with delivery software.

2. Inventory management

Inventory control is among the logistics functions that are often grouped together under the inventory/warehousing umbrella. For the purposes of this guide, we separate inventory and warehouse management processes.

Inventory refers to stocking finished goods in a storage facility. In order to support the transportation and delivery processes, inventory control requires information for maintaining inventory records, ensuring safety, predicting demand for goods, and, of course, reordering stock.

Inventory logistics

Inventory logistics remains on the borderline between inbound and outbound logistics, as it involves both supplier relationship management (inbound logistics) and order fulfillment (outbound logistics).

Therefore, inventory management is an important part of supply chain management and needs to be used efficiently. This means careful, data-driven assortment planning and timely restocking.

3. Warehousing

Warehouse management is a natural extension of inventory activities. While inventory covers all locations and, hence, all inventory for order fulfillment, warehousing is limited to tracking stock movement within a warehouse.

At the warehouse level, handling, packing, and shipping workflows are established.

Both inventory and warehousing require sophisticated tools that support the main functions and help reduce costs via automation and reduce machine downtime. Especially if your company delivers from multiple warehouses and needs complex logistical solutions.

Warehousing transportation

One of the biggest trends in order fulfillment in 2023 will be micro warehousing and micro fulfillment. By strategically placing inventory in small warehouses located in densely populated areas, retailers are planning to cut transportation costs and encourage more pickups.

Because automated routing and route optimization can be done with unlimited departure locations, micro fulfillment can be very cost-efficient. You can nail warehousing transportation activities and delight your customers with on-time deliveries.

4. Packaging

Packaging includes all the activities and operations implemented to prepare goods for handling and transportation to and from customers - in case of reverse logistics and returns specifically. Packaging is one major logistic function as it determines delivery success.

First and foremost, packaging needs to be compliant with safety and any customs regulations that may halt your delivery service.

Moreover, it's important that packaging matches your storage and vehicle needs, as well as meets the demand for sustainable materials and other green logistics aspects.

5. Cargo handling

Cargo handling is one of the major logistics management activities that can't be overlooked when discussing supply chain functions. It's closely related to packaging and determines logistics costs in a very real way.

Getting the package and handling procedures right is the foundation of physical distribution. It's equally important for safe storage and transportation.

No consumer enjoys damaged products or the wrong product delivered to their door.

No company wants ever-rising shipping costs because couriers have to make many trips to one customer to get the order right.

Tips for cutting handling costs

There are many things you can do to improve the cargo handling function of logistics and significantly reduce your shipping costs.

QR/barcode scanning

QR or barcode scanning is a cost-efficient way to improve your delivery success. By implementing an online barcode scanner or Track-POD's free offline barcode scanner app, you give your couriers the tools to scan all goods within one load to make sure they're heading for the right address.

Fleet optimization

Route optimization and fleet optimization both serve the purpose of reducing your cost per delivery by maximizing your logistical resources.

For example, by collecting all information on your fleet capacity and drivers' working hours, Track-POD's route optimization algorithm creates the fastest, cheapest routes with no vehicle storage wasted.

Contactless delivery

Contactless delivery is a way to minimize cost per delivery and improve customer service at the same time.

By making an upgrade to a contactless & paperless system, you meet the demand for no-contact deliveries while also solving a major logistic challenge of catching your customer at their place of residence at the designated time.

6. Transportation

Last but not least is the transportation itself. Naturally, transportation is among the main logistics functions, if not the main.

It's required at every step of every supply chain, and the way companies build their transportation management system and functions determines the success of supply chain management.

We've already talked about many important aspects of logistics activities. From storage and warehouse to material handling and fleet optimization.

Let's review more logistics activities that help companies improve their customer service and up the rate of successful deliveries.

Route optimization with ETA

Route optimization is automated and supercharged route planning that makes the most of your fleet and driver resources.

Estimated arrival time (ETA) is available as a dynamic time for the dispatcher at the back office and as a fixed time for the customer, which means they're more likely to be home on time.

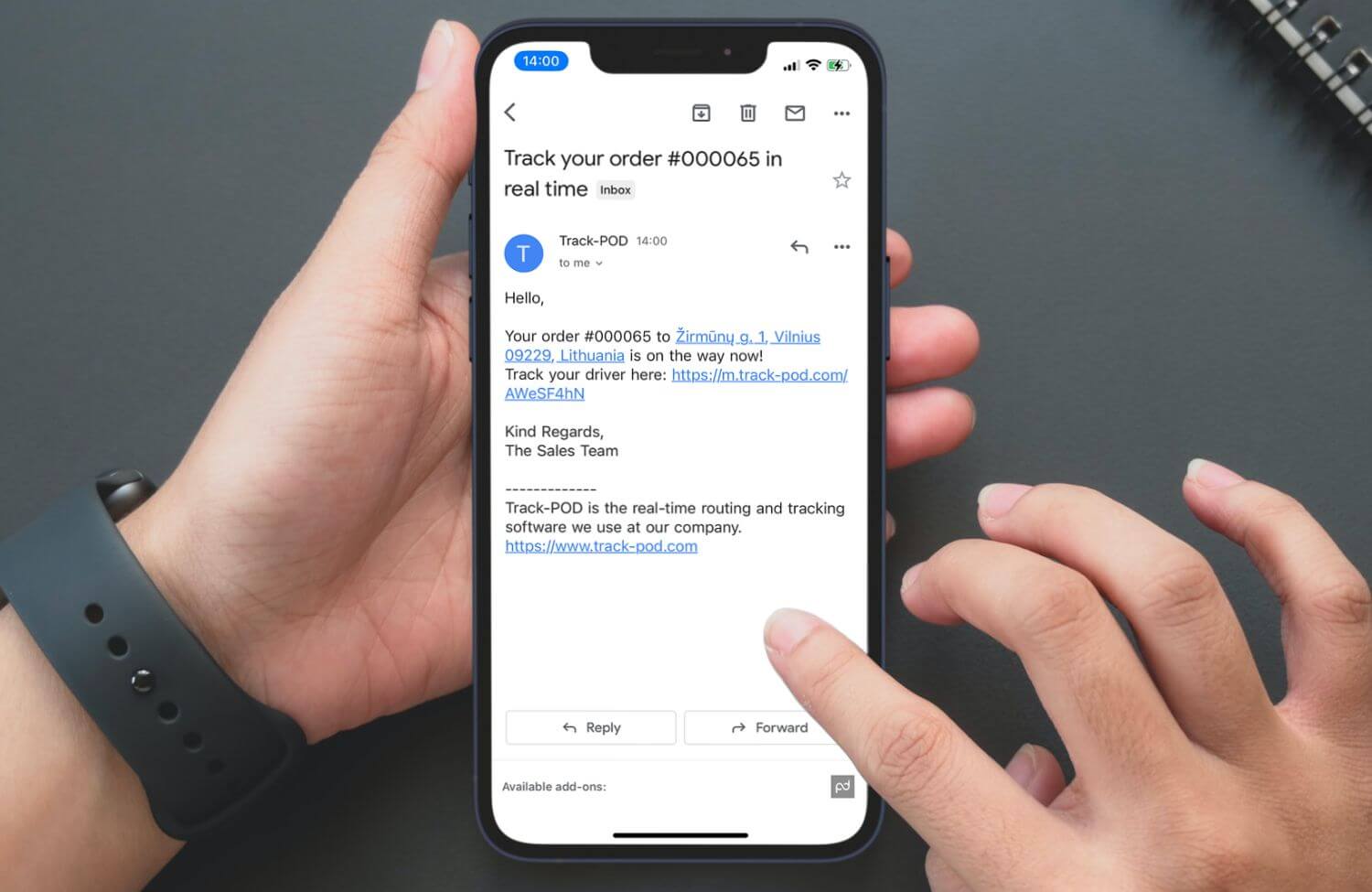

Customer notifications and live tracking

Live vehicle tracking and delivery notifications are essential for the consumer to be at the center of the transportation process, which greatly improves customer service. Not to mention your dispatchers can see real-time locations of all drivers en route at all times.

Proof of Delivery

Electronic Proof of Delivery (ePOD) is a document generated by your delivery management system as soon as the product or products have been delivered from the warehouse to the customer at home.

With a system like Track-POD, you can have your customers receive a custom ePOD right after the products have been left at their door. Your drivers can also collect electronic signatures, take photos, or add custom notes, as a part of ePOD.

Shippers portal

Shippers portal, i.e. a place where your regular customers can log in to add, track, and manage their orders independently, is an invaluable part of any supply chain management process.

Track-POD has a Customer Portal for shippers to log in and help you fulfill your logistics functions.

7. Monitoring

Monitoring of logistics performance is a critical function that empowers businesses to track and manage their operations with precision and efficiency while strengthening supply chain risk monitoring against cybersecurity threats.

By putting in place strong tracking systems and technologies, companies can gain real-time visibility into their supply chain and detect anomalies, unauthorized access, or suspicious system behavior before cyber risks impact logistics operations.

Businesses can monitor the movement of goods, check inventory levels, analyze delivery performance, and get important insights into their logistics processes by using sophisticated monitoring tools.

IoT devices in logistics

IoT (Internet of Things) devices have changed the way logistics tracking is done by giving companies more insight and control over their supply chain processes.

These smart devices, embedded with sensors and linked to the internet, can track and send real-time data on various aspects of logistics, including temperature, humidity, position, and state of goods.

By using IoT devices, companies can keep an eye on their stock levels, track vehicles and packages, and find issues or deviations in real time.

IoT devices make monitoring function in logitics easy, accurate, and highly actionable. Some of the examples of modern IoT devices are GPS trackers, RFID tags, condition monitoring sensors, temperature sensors, and smart warehouse management system.

Analytics tools

Analytics tools integrated into delivery management software play a crucial role in enhancing the logistics monitoring process.

These tools leverage advanced data analytics and visualization to provide businesses with valuable insights into their delivery operations.

Track-POD offers a variety of shipping reports, including real-time analytics, ready-made, and customizable reports that let you choose the data points you need. You can extract specialised reports like driver statistics, trip summaries by routes, order and item overviews, cost savings analysis, and route costs.

Delivery management reports let users evaluate staff effectiveness, track progress, and make efficient delivery decisions.

With the ability to closely monitor their logistics operations, companies can stay one step ahead, ensuring smooth operations, timely deliveries, and the ability to adapt swiftly to changing customer demands.

Before you go

There are many logistics activities because there are different logistics functions. They all support information processing, storage in different warehouses, product and material handling, customer service, logistics monitoring, and a lot of other things involved in physical distribution.

I hope this blog post gives you an overview of the role logistics plays in supply chain management, as well as the respective functions it fulfills.

If you're interested in any of the logistical and business solutions reviewed above, try Track-POD for free or book a demo to see our cost-efficient transportation management system in action.

- Delivery Management

- Transportation management

About The Author

Alina Kostukova

Skilled marketing content creator with a background in digital media and public relations. Focused on creating first-rate text and visual content that stands out and tells compelling stories.