Best Route Planning Software in 2025

This guide compares Track-POD, RouteManager, Circuit, and Upper, covering features, pricing, routing quality, and best-fit scenarios to help businesses choose the best route planning software for 2025.

Read More

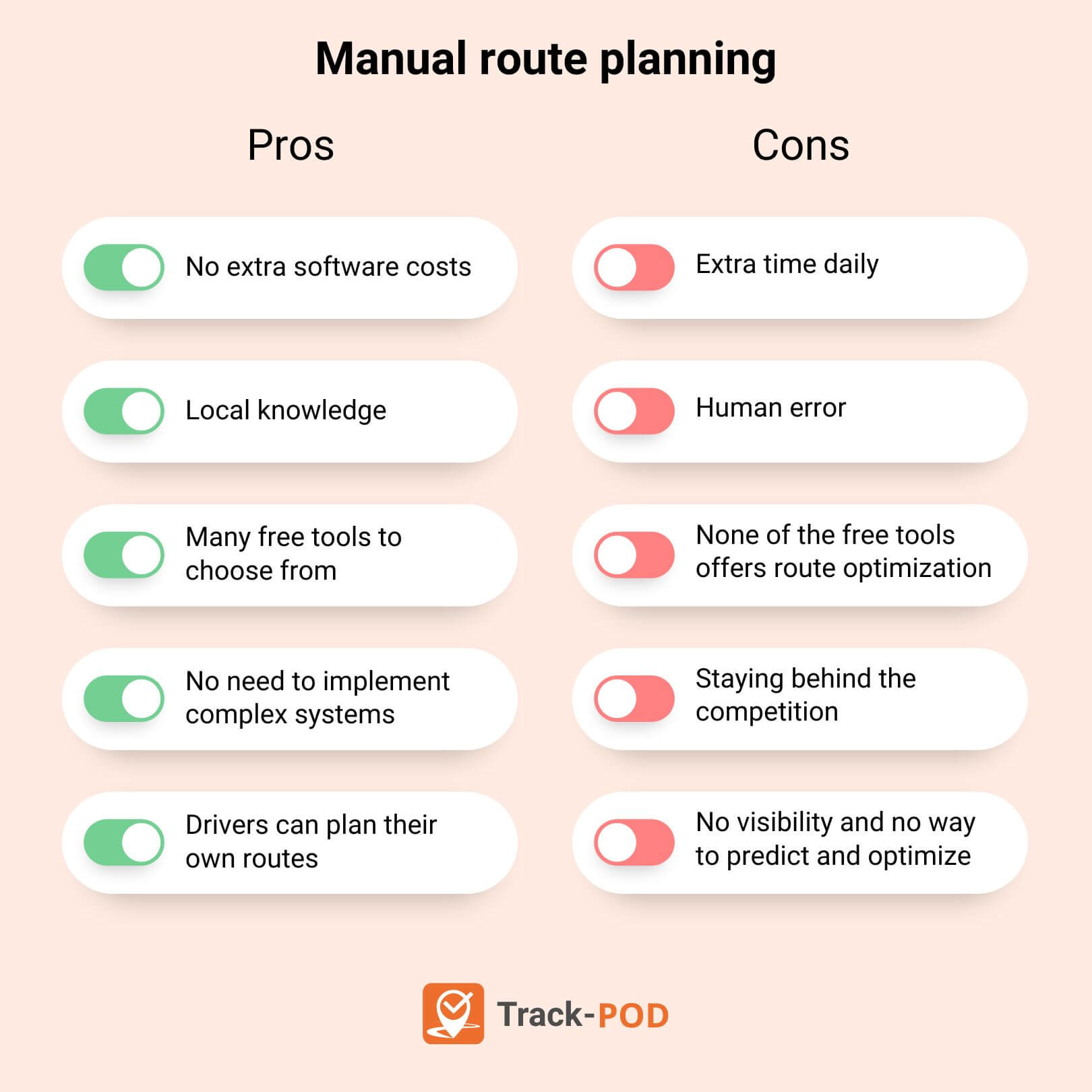

Manual vs automated route planning is a greater rivalry than some would expect.

While many delivery operations are enjoying the benefits of fully automated vehicle routing, a substantial amount of companies are still routing their fleets the old way - and not without a reason.

What is it about manual routing that keeps logistics operations from investing in route planning software? What risks do you need to be aware of? How long does it really take? And, finally, is automated vehicle routing worth it?

Read on to see for yourself.

Manual route planning has been around ever since humans had vehicles and maps to navigate. Until very recently, private travel could only be routed manually, and this was the prototype for commercial travel.

To this day, many logistics operations keep route planning a manual task. Why do they do it? Let's find out.

Let's be honest: changing your ways is never painless. Especially when the old way has been working fine for decades and it's hard to see a reason to change.

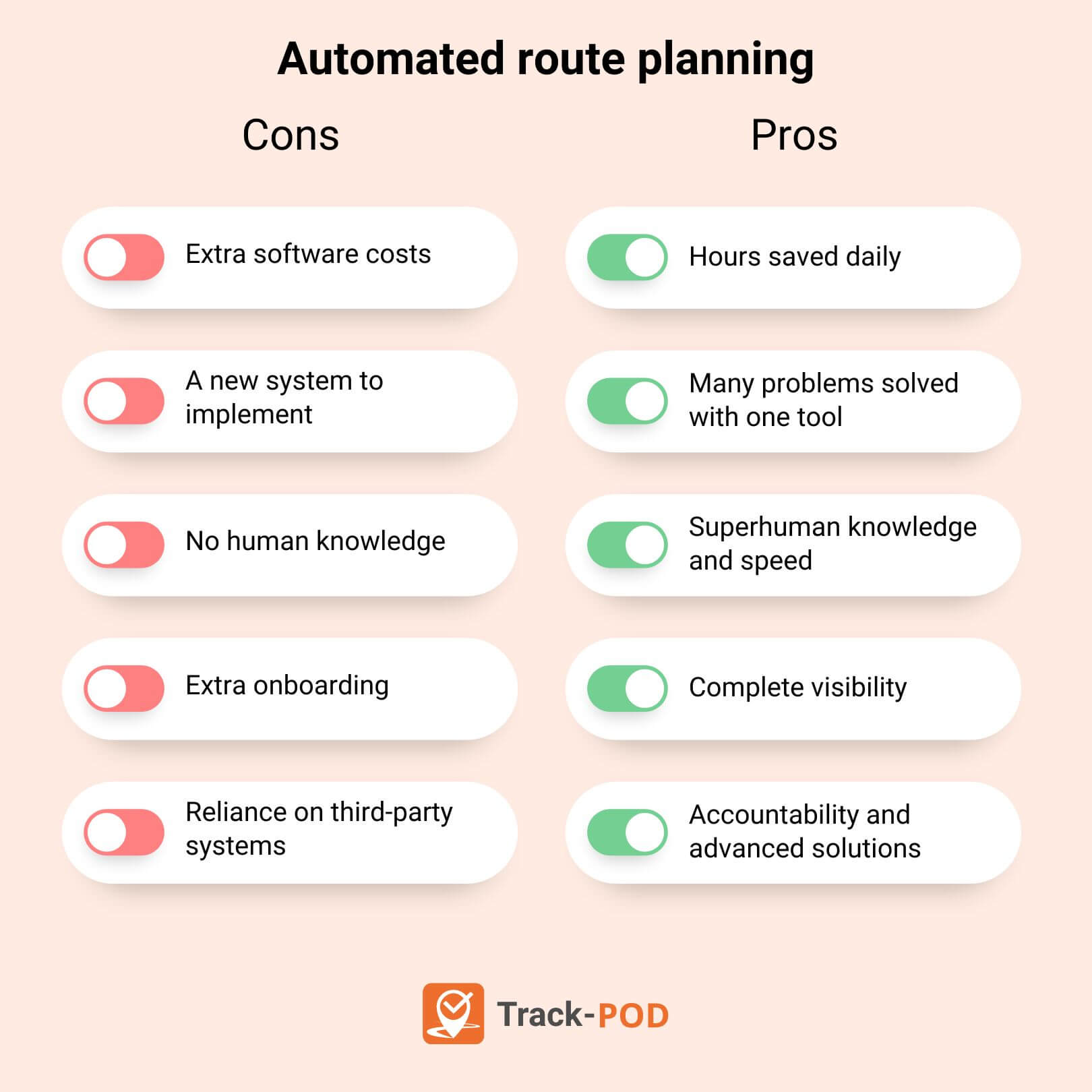

Automated route planning comes with its own risks that are especially clear to small business owners and businesses whose main task is not transportation itself.

Let's briefly review the pros and cons of automated route planning systems.

Extra costs is the biggest deal breaker for logistics operations that stick to manual route planning. While this is very rare for courier and delivery services, other businesses have their reasons to cut costs on route planning.

In industries where transportation is not the only job the staff needs to do (think field services), route planning is often overlooked. Especially if drivers operate their own vehicles (aka grey fleet) and start routes from home.

As is often the case with automation, extra costs pay off in hours of employee time saved daily, not to mention increased efficiency and the ability to do more with additional tools.

Knowledge of local couriers is priceless and no AI existing today is able to apply local knowledge and experience to building routes for vehicles. However, local knowledge comes with human error and a limited human capacity.

It's one thing to route one vehicle to one destination and another - to route the same vehicle to multiple addresses a day, or to route multiple vehicles with multiple drops a day.

Mistakes are bound to happen when a person needs to route many vehicles with different capacities a day. This is no fault of a person. Instead, this is a call for automated solutions.

Free tools like Google Maps are used by millions of people every day to route their vehicles. One crucial thing they lack is route optimization.

What does a route optimization algorithm do? It applies additional conditions to route planning to make it more precise. Vehicle capacity, road restrictions, customers' preferred time slots, and many more.

In a nutshell, route optimization is what maximizes your route planning and offers solutions to every challenge and use case you may encounter.

Adopting a new system always comes with extra costs, extending far beyond the license itself. Staff needs to be onboarded, all integrations need to be set up, and all gaps need to be closed before you can go full speed.

However, the longer you refrain from automating your tasks, the further behind your competition you are. Automation is the future, especially when it comes to automation that builds up on what you have and makes you more efficient right away.

The beauty of route planning software is that it extends far beyond route planning itself. From shipping labels and barcode scanning to real-time customer notifications - all of this helps you future-proof your business at the cost of a route planner.

Having drivers plan their own routes is a way for many businesses to save money on hiring an extra dispatcher or implementing extra route planning tools. However, it comes at a cost of visibility and efficiency.

Even if you have a dispatcher on board but they need to plan all routes manually, there's no way to track all drivers without installing physical tracking devices, which always comes with additional costs.

Using a route planner app for teams is a way to keep track of all drivers in real time and on a single map, not to mention analytics and optimization.

As you can see, both manual and automated route planning come with their own pros and cons, and it's important to review all of them before you invest in a new system.

To help you make an informed decision, here are some points to consider.

If your unit of measurement is hours and not minutes, you might need to research automated route planning systems.

While human error is inevitable in any logistics operation that includes humans, much of it can be eliminated with automated solutions such as multi-stop route planning, EV routing, etc.

Any decent route planner for teams will enhance your operation with solutions to all types of logistical challenges. Get on a new level with customer notifications, predictive analytics, and electronic Proof of Delivery by investing in all-in-one tools like Track-POD.

Not all route planners are the same. Some require a lot of setup, add-ons, and integrations. Some offer all solutions and features out of the box and boast intuitive interfaces. It's only a matter of time before you find a system that is truly easy to implement.

Manual vs automated route planning is an important question to settle for every business that transports and delivers. It's not as simple as 'automated is better by default' as business needs and limitations can be different.

One thing that is beneficial without a doubt is knowing your options. I hope this article helps you get a better picture of yours.