A Comprehensive Guide to Supply Chain Visibility: How Important Is It?

by

Jenna Bunnell

August 01, 2022

In this post, guest writer Jenna Bunnell offers tips on improving your supply chain visibility.

How do you keep customers happy? Some would say by providing the best customer service, investing in new technology, improving speed, or lowering the price. Others focus on customer experience, tailoring messaging and offers to the needs of the buyer.

Neither of these answers is wrong, but there is one even more critical factor. To keep a customer happy, you need products. ‘Well, that’s a bit obvious’, you might be saying. Whilst this might be true, many businesses still fail to get their products delivered on time. Why? Because they lack full visibility over their supply chain.

With full visibility, you can follow a product on its journey to reaching a customer. But first things first, what is a supply chain?

What is a supply chain?

For a second, let’s put ourselves in the shoes of a customer. You’re browsing online and see a product that you like. You purchase the item, and a few days later, it arrives. Simple, isn’t it?

But what the average customer doesn’t realize, is the complex set of processes involved in getting a product to them. This set of processes is the supply chain.

What is supply chain visibility?

Supply chain visibility is the ability to track each level of your supply chain.

In your product’s supply chain, you’ll likely work with third parties to manage certain aspects, such as acquiring supplies and managing the delivery. There’s a high chance that one or more of these elements will run into trouble. At this point, your entire supply chain risks grinding to a halt.

For example, let’s imagine that you sell household appliances. To deliver a product you first need to source parts, such as electronics and other materials. You then need a team to assemble the products before they are delivered to customers.

But what if one of the suppliers is unable to deliver the parts that you need? Suddenly, you’re unable to manufacture products. Customers are left waiting and might even cancel their orders. In short, this can be a bit of a crisis.

Any of the following can impact your supply chain.

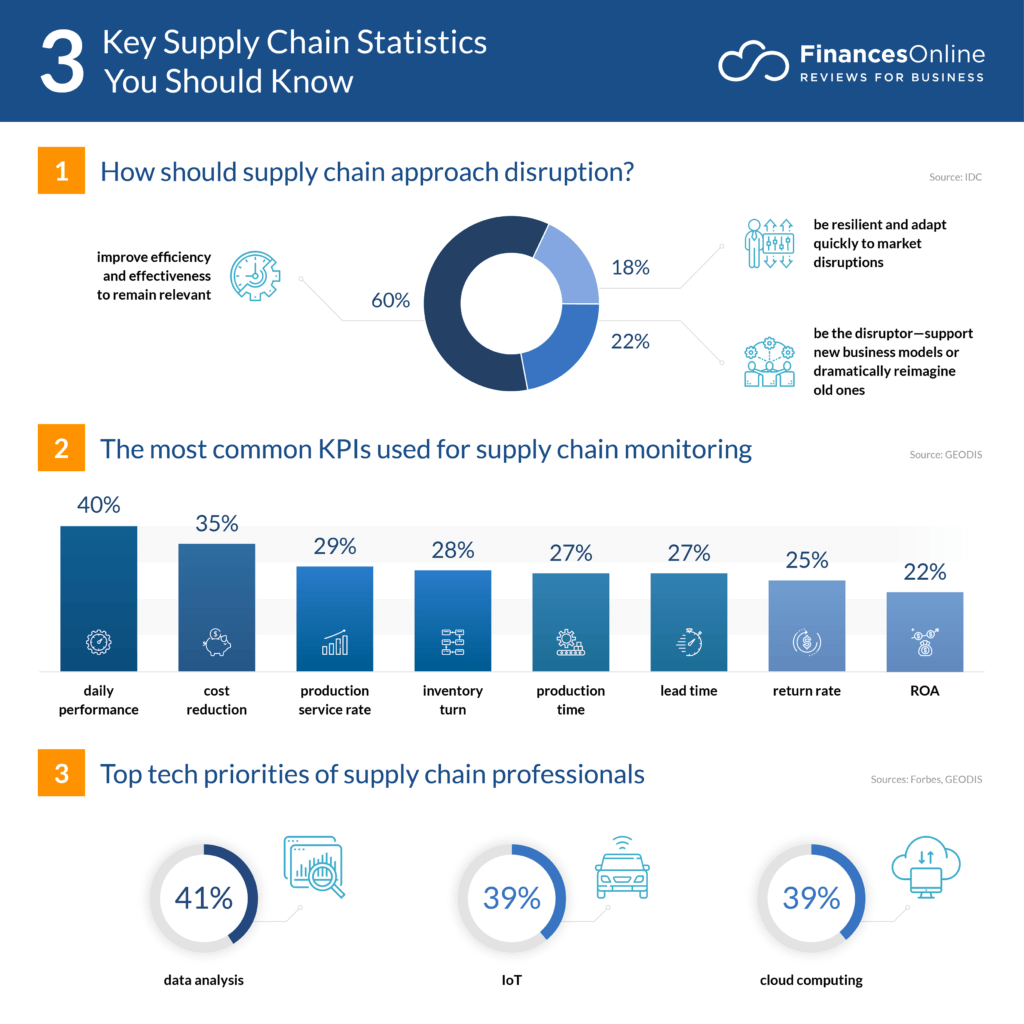

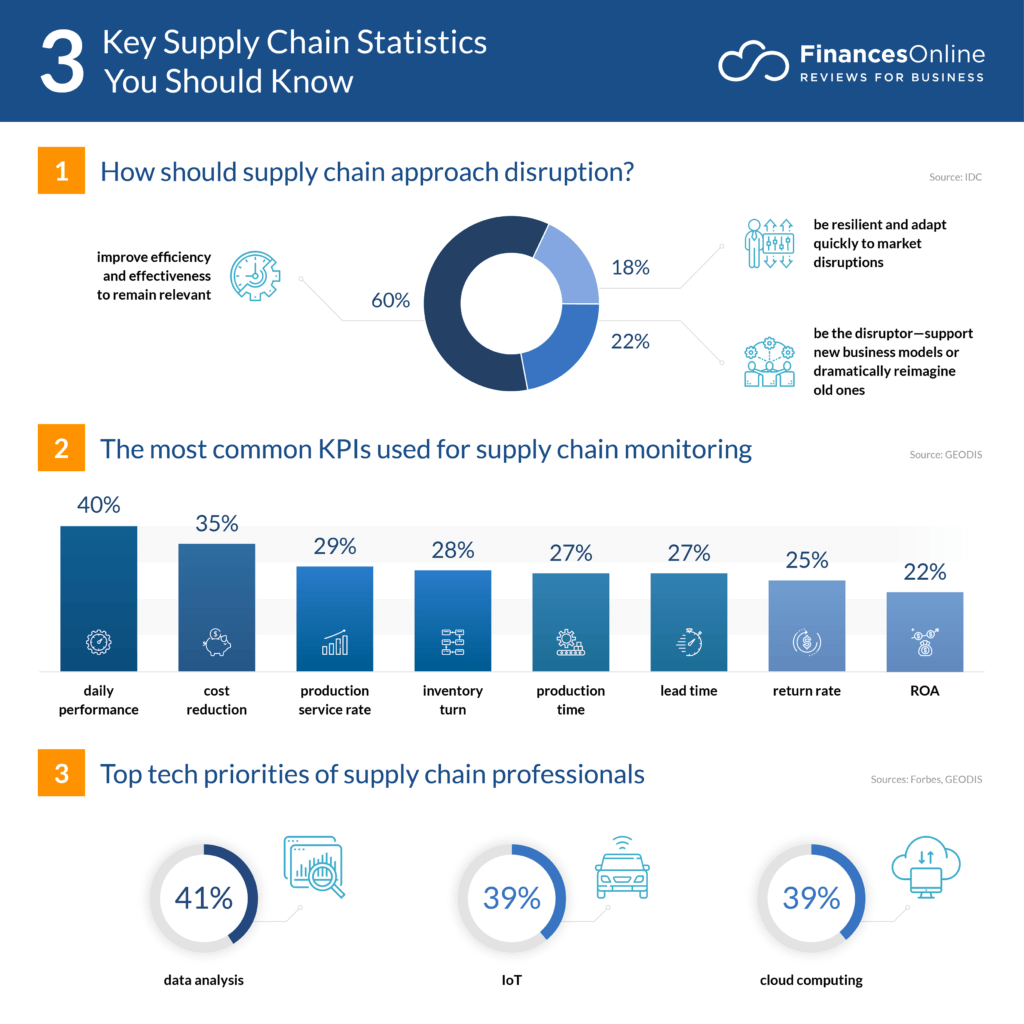

If you’re still unconvinced about the importance of visibility, you only need to look at the stats.

Supply chain issues have negatively impacted 75% of companies.

But what could you have done to prepare for disruptions? This is where supply chain visibility comes in.

With full visibility, you’ll have a clear view of each of the processes involved in bringing a product to your customers. This means that you can spot weak points, and plan for different scenarios. You might not be able to prevent all disruptions, but you can reduce their impact.

But how do you gain supply chain visibility? Let’s find out.

Map out your supply chain

For total visibility, you need a clear view of your supply chain. Start mapping out the different processes involved in selling a product. This should start with sourcing materials and end with a customer taking delivery of their product. At each stage, are there any risks?

Take time to consider every scenario, even if it seems unlikely. For each pain point that you identify, try to start thinking about a potential solution. For example, you might find your warehouse is at risk of flooding. To mitigate this issue, you might install flood protection.

The more time you give to planning different scenarios, the greater your visibility will be.

With high levels of visibility, you’ll be able to gain access to some of the following information.

-

The status of materials and parts needed to manufacture an order.

-

The delivery date and estimated time of arrival from a supplier.

-

The progress of orders.

-

Details relating to shipping.

Think bigger

You might think you’ve already got a clear idea of your supply chain.

Think again.

Look over your supply chain, there’s a good chance that you’re missing out on a key element. You might have included your suppliers, but have you included their suppliers?

Just as you have a supply chain, so do the third parties you work with.

If their supply chain is disrupted, they will no longer be able to supply you with the parts that you need. This means that your supply chain will also become disrupted. To gain full visibility, you need to look beyond your own processes.

For instance, let’s imagine you sell bicycles. It’s likely that you won’t manufacture bikes yourself – instead, you’ll receive them from a manufacturer. In this instance your manufacturer sources gears from an external supplier. If gears aren’t available, bikes can’t be produced, and you don’t have products for your customer.

So, when plotting out your pain points, pay particular attention to your suppliers. Do you have eyes on their supply chain? If not, it’s time to start carrying out research.

If you want visibility over your suppliers' supply chains, you should include this in your contract. If you’re making legal agreements digitally rather than on paper, be sure to review esignature legality.

Get to know your suppliers

A key part of supply chain visibility is knowing when an order will be completed. There will be certain aspects of the process that you already have a good grasp on.

For instance, you will know how long it will take you to manufacture a product. But you might not know how long it will take for your supplies to arrive so that you can begin your manufacturing process.

The only way to find this information is to create stronger ties with your suppliers. Why not invest in phone systems for small businesses and get in touch? By establishing a strong working relationship with them, you’ll get a better idea of when supplies will arrive.

Your customers will be eager to know when their products will arrive. By having a clear view of the process, you can provide a stronger estimate.

Keep track of your deliveries

So, you’ve taken delivery of parts and manufactured a product? Delivery is the last hurdle that you’ll need to navigate. This step is critical, as customers won’t be happy if their item isn’t delivered on time or arrives damaged.

If you’re outsourcing deliveries to a third party, it's vital that you take time to research all your options. Delivery will be out of your hands, and you’ll need a service that is communicative so that you can maintain good visibility.

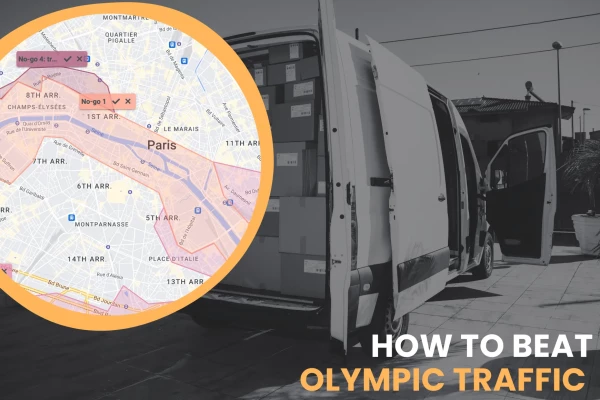

Of course, there are steps you can take to further increase visibility during the transportation and delivery stage. For instance, Track-POD last mile logistics software powers complete visibility for both businesses and customers.

Dispatchers can see where their drivers are located throughout the day and customers can track their packages in real-time.

Bring in new tech

In recent years, many businesses have undergone a digital transformation. It’s not hard to see why. Technology can play a part in many different aspects of running a business. This ranges from the hosted phone service to marketing automation technology. Your supply chain can also benefit from the tech.

Currently, your supply chain is probably mainly managed by humans. With the right people in place, this can be effective. But even the most seasoned workers make mistakes sometimes. As explored above, a small error in a single part of your supply chain can have big consequences.

But how can technology play a role? You’ve probably already heard of artificial intelligence (AI), although thanks to sci-fi, maybe not always for the right reasons. But AI (currently) has no plans to take over the world. Instead, it can be used to make your life easier.

AI almost certainly already features in some aspect of your life: powering your smart assistant or helping to facilitate searches online. But AI has big implications for business too. Using a technology called machine learning, AI can replicate human thought patterns. An AI chatbot can process tons of data and suggest instant solutions to complex problems.

The chatbot's emergence, such as chatGPT, takes over the game if used correctly with the best chatGPT marketing prompts. The correct prompts use generate correct outcomes that are similar to human thoughts.

This means that it can examine your supply chain and reinvent processes. This can provide greater visibility and ensure your chain remains error-free.

Of course, AI relies on a lot of data to work effectively. But simply having the data isn’t enough. To be useful, data needs to be stored in a sensible and organized way. Think about the way your data is stored – resilient distributed datasets are a data structure in which many modern data sets are managed.

Supercharge your supply chain

As a business, you’ve probably invested in ways to bring in new customers. This might mean using a software referral program or rolling out ad campaigns. But this work is all for nothing if you can’t persuade customers to stick around.

That’s why supply chain visibility needs to be your number one priority. The longer a customer is forced to wait before they receive a product, the more frustrated they’ll become. Ask yourself, could your supply chain visibility be improved?

The process starts by taking a cold, hard look over your supply chain. Find pain points and plan for different scenarios. Are you getting all the information that you need for maximum visibility?

If not, now is the time to start planning and deciding on a new route going forward.

The steps outlined in this article will set you on the right path. Clear visibility is the route to customer happiness. So, what are you waiting for? Start boosting your supply chain visibility today.

About The Author

Jenna Bunnell

Jenna Bunnell is the Senior Manager for Content Marketing at Dialpad, an AI-incorporated cloud-hosted call center service for small businesses.